WebCore Technologies, Miamisburg, Ohio, USA, was awarded the funding as part of the Department of Energy (DOE)'s Small Business Phase III Xlerator programme. Phase III Xlerator awards were created to help small businesses develop manufacturing processes to scale up production of their new, proven technologies, creating new markets and new jobs.

WebCore was selected for its next phase development and commercialisation of TYCOR W, an engineered core material for composite structures which can be used to manufacture wind turbine blades. The company will use the funding to expand production capacity of TYCOR W at its Miamisburg manufacturing facility and support ongoing development of enhancements to its TYCOR technology platform.

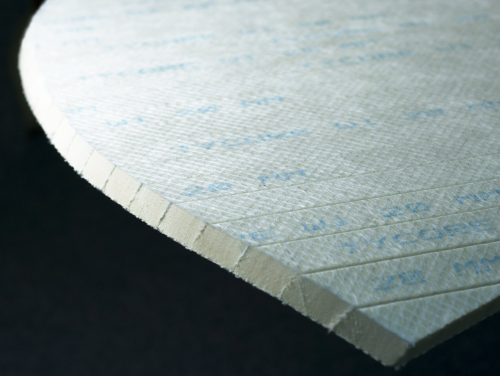

TYCOR W

WebCore’s TYCOR W technology combines fibre reinforcements, such as E-glass roving or mat, with closed-cell, low density foam in an engineered architecture. The patented core material has been in use for over 2 years in utility-class wind turbine blades and is undergoing qualification for use with additional 1.5-3 MW turbines that have blade lengths in the 40-60 m range.

1-inch thick TYCOR W is reported to save an average of 0.5 lb/ft2 of weight and reduces resin usage by 0.2 lb/ft2 when compared to 1-inch thick balsa wood core material. WebCore’s production process is said to optimise TYCOR W sheet sizes, improving kitting yield by up to 10%.

Further information

In the feature article Bigger blades mean better opportunities for new core materials,Dr Rob Banerjee, Vice President, Business Development at WebCore Technologies, discusses how the company's TYCOR W core material can help manufacturers of large wind turbine blades optimise their designs.