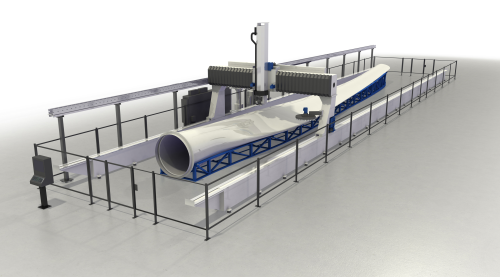

The Agile Gantry is a CNC machine-tool equipment platform that provides unlimited X-axis range, 40 m/min traverse speed, automatic tool change and five servo-controlled axes. It performs coating, blade machining and finishing quickly, increasing productivity and quality, while reducing the need for manual labour.

Designed for five-sided part access, the equipment supports a wide variety of applications and processes such as: cutting tools; spray heads; water-jet cutters; chopper guns; and finishing tools.

It can be used to produce complex mould geometries in high-density foam, apply coatings, or trim and finish free form, contoured parts, and is said to be ideal for marine, automotive and aerospace applications.

Using a modular rail system to create any X-axis length required, the rail system can be placed below the factory floor, above it, or elevated to create a high rail configuration. A variety of work-holding systems can be adapted and positioned between the rails. The gantry cross rail provides 5.5 m of Y-axis travel and 2.5 m or more of Z-axis reach. Servo-controlled contouring is simplified with rotary A and C axes (spindle tilt and wrist roll) that provide ±100° and ±200° of movement respectively. The maximum feed rate for the linear X, Y, and Z axes is up to 40 000 mm/min and up to 3600 degrees/min in the rotary axes. Linear axes are powered by dual electronically preloaded AC servomotor rack-and-pinion drive systems.

The machine's liquid-cooled, 15 kW AC spindle delivers a 0-24 000 rpm speed range and accommodates an HSK63F tool shank. A high-capacity vacuum system with spindle shroud is available to catch dust and chips. A drum-type tool changer holds 16 tools for automatic tool changes.

The equipment is controlled by a Siemens 840D CNC with colour screen, handheld pendant and hand wheel controls. Using a spindle touch-probe, the machine can locate a part or fixture, allowing the control to align the part program execution to the actual part position. Spindle probes can also be used for in-process part measurement by the machine.