The rapid material placement system (RMPS) introduces integrated manufacturing with automation and repeatable process control to what has largely been a manual or piecemeal-automated process.

RMPS is an automated blade moulding facility capable of spraying in-mould coatings, dispensing/lay-up of glass and carbon fibre materials, and dispensing/application of adhesive.

It brings 3 m/sec lay-up speed to placement of materials in wind turbine blade skin, spar cap, and sheer web moulds, with laser- and vision-based wrinkle detection in cross or longitudinal directions. Depending on the laminate schedule, the system is said to reduce lay-up time 85% on a 45 m wind turbine blade.

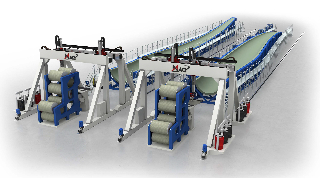

Programmed off line, the computer numerical control (CNC) system consists of a gantry system with multi-axis end effectors capable of manipulating spray heads and adhesive applicators, as well as tooling for spooling and placing materials.

After application of gel-coat with spray-head tooling, a ply-generator with a ten-roll magazine of material cuts and dispenses plies to the lay-up end effector on the gantry.

The lay-up end effector spools up the material supplied by the ply generator. As the fabric is paid out onto the mould, a pair of articulating powered brushes smoothes it to the tool surface. The lay-up system is mechanically repeatable to ±2 mm, with application tolerance of ±5 mm.

Two such gantry systems adjacent to one another can each produce a 45 m wind turbine blade shell half in less than two hours, with half the manual labour of conventional methods.

Quick-cure mould system

MAG has also developed a patent-pending quick-cure mould system utilising its tooling. The moulds are produced using the customer's computer assisted design (CAD) data.

The system yields a finished blade to spec with each cycle. It can be infused with resin in an hour, followed by a two-hour cure, about half the normal time. Like the lay-up system, the infusion/curing system includes process control metrics for resin metering, temperatures and blocked channels, with alarm limits.

On the finishing side of wind turbine blade automation, MAG is introducing a five-axis machining system for root drilling/milling/sawing.