Chemical company INEOS says that its manufacturing sites in Texas and California have been awarded certification from International Sustainability & Carbon Certification (ISCC).

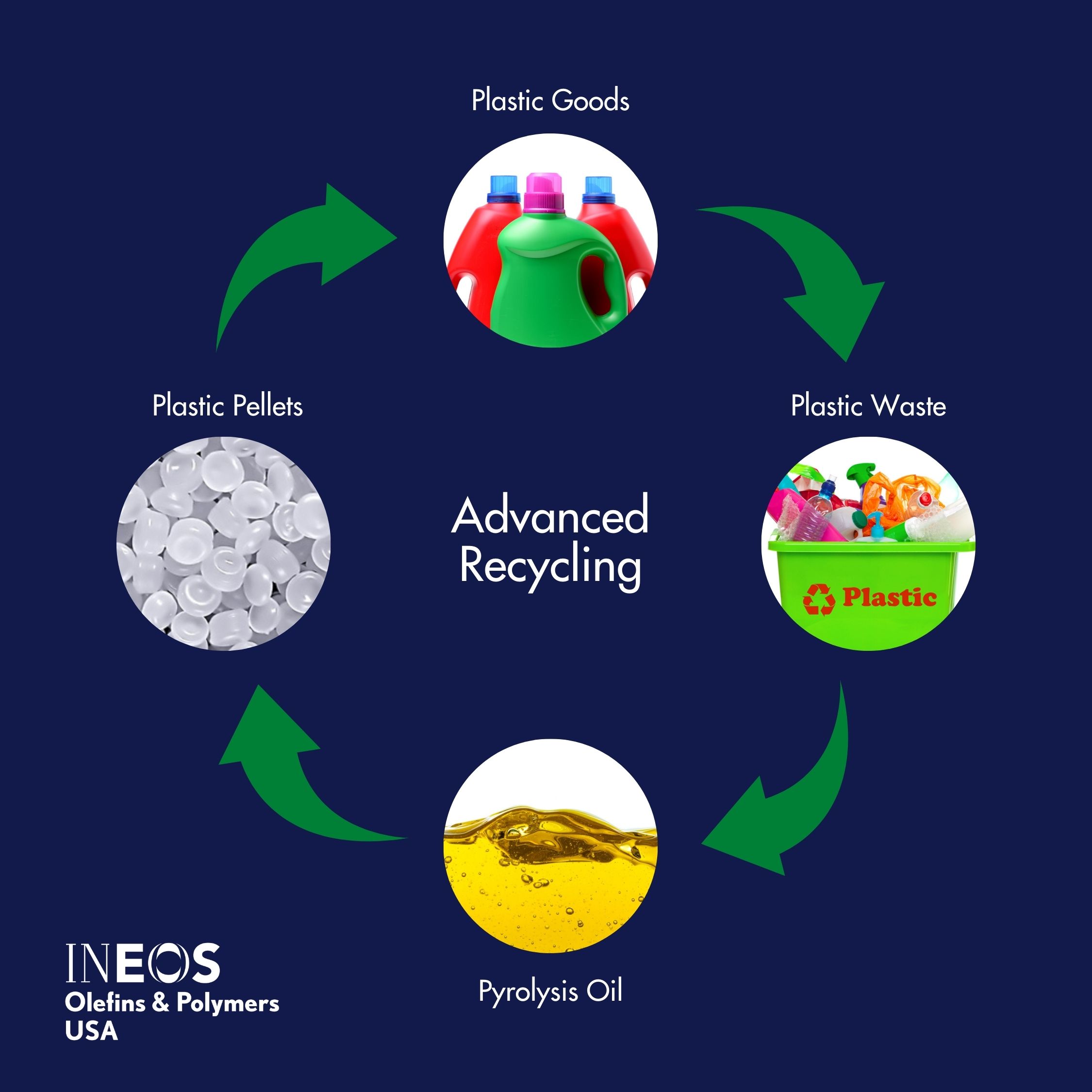

The company has recently carried out successful, commercial-scale trials of advanced recycling technology for the production of ethylene, propylene, high density polyethylene (HDPE) and polypropylene (PP). Advanced recycling, also known as chemical recycling, converts waste plastic destined for landfill, back into a liquid raw material for use again in next generation plastic production. This technology can be used for many types of plastic including mixed plastic waste streams that are normally difficult or impossible to process with traditional recycling, INEOS says.

The technology enables plastics to be recycled back to a raw material stream and returned to the market as new product from recycled material.

‘Using difficult-to-recycle waste streams as a new raw material is a step-change,’ said Mike Nagle, CEO of INEOS Olefins & Polymers USA. ‘This investment is beneficial to INEOS and our customers but also for the overall global issue of plastic waste and the management of essential plastic products.’

‘We are committed to the transparency and challenge that certification such as ISCC PLUS brings to our organization and our industry,’ added Phil Fusco, vice president of polymers.

This story uses material from INEOS, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.