Following an extensive testing procedure, which was witnessed by Airbus, Boeing and the FAA, the CACRC qualified Epocast 52 A/B as a structural repair material for carbon-epoxy components to be processed by wet-lay-up (vacuum bagging).

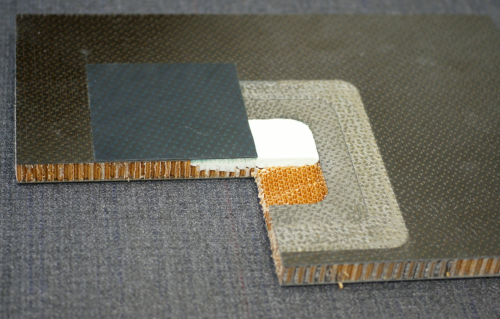

Wet-lay up is often the preferred process for repair due to the simplicity of storage offered and the use of two component resin and dry fibres, Huntsman notes.

Epocast 52 A/B is reported to combine low temperature vacuum bag curing with excellent hot/wet performance (service temperature up to 177°C). This system is also qualified to BMS 8-301, Class 1, Grade 2; AIMS 08-01-002-01 and AIMS 08-02-002-01.

“A repair has to restore a damaged structure to its original state," explains Philippe Christou, Head of European Technical Support, Huntsman Advanced Materials.

"It has to be airworthy, durable, damage tolerant and capable of exceeding the life of the aircraft. Repair solutions need to be designed to meet the needs of the OEMs, the airline users and the airline repair shops. As the use of composites in airframe structures increases, several challenges must be addressed. Among these, repair methods and their standardisation are of upmost importance.”

The CACRC aims to develop methods and procedures for the repair of composite structures on civil aircraft structures. The organisation involves members from airframe manufacturers, airline users, material manufacturers and aviation authorities. CACRC and the OEMs are responsible for the qualification of repair materials.