The ACCE facility serves as the headquarters for ATK's commercial aircraft programmes and supports the manufacturing of composite airframe and engine components for the Airbus A350 XWB, and General Electric and Rolls-Royce engine programmes.

As previously announced, ATK has received commercial aircraft component orders exceeding US$1 billion over the last few years.

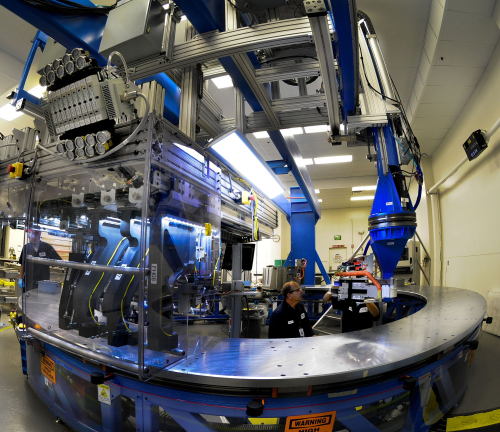

The 615 000 ft2 ACCE building is dedicated to high-rate composite manufacturing. Approximately 100 000 ft2is committed to clean rooms which accommodate its patented automated stiffener forming technology and engine wrap machines.

ATK says initial production of 700 parts per month will accelerate in line with customer needs and market expansion. At rate production levels, the ACCE facility will produce 10 000 parts per month.

The ACCE facility is located adjacent to ATK's existing Utah composite facilities which manufacture military aircraft composite structures.

"Our new Aircraft Commercial Centre of Excellence is a key component in our strategy to capitalise on the growing demand for modern, more efficient commercial aircraft," says Mark DeYoung, ATK President and CEO. "Our longstanding experience in highly-engineered composite structures and our expertise in automated manufacturing methods are now matched by a state-of-the-art production facility."

"Combined with our $500 million of orders for military aircraft composite structures, ATK is in two high-growth markets for the long-term," adds ATK Aerospace Systems President Blake Larson.

ATK expects to add up to 800 future jobs in support of composite manufacturing in Utah.