“This product noticeably exceeds the aircraft specifications for low temperatures, room temperature and relatively high temperatures,” states Karin Eisenblätter, Communications Manager at the Swiss materials specialist.

As a result of its simple handling and long shelf life, Araldite EP1000AB also provides very promising options for additional applications.

Araldite benzoxazine is an alternative for prepreg production. This is a new polymer class for applications in the transport industry, especially for internal components in aircraft. They are used where phenol resins need to be replaced due to their toxicity.

“The advantage of Araldite benzoxazine is that large quantities can be produced in the required quality for the aerospace industry," according to the spokesperson. "Thanks to comparable polymer structures, the material also has the behaviour in fire of conventional phenols. The mechanical characteristics are even better.”

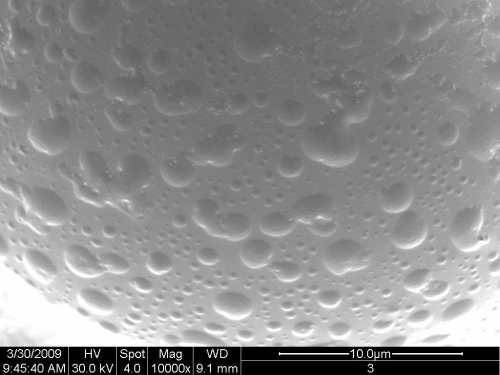

With Eposert, Huntsman also has new, preformed syntactic inserts for reinforcing honeycomb structures. Deep-frozen syntactic Epocast 1614-A1 forms the basis here for the inserts. These consist of preformed, hardened components, which are produced in individual diameters, lengths and configurations according to customer specifications. Since they are free of cavities, a higher compressive strength can be achieved at temperatures up to 177°C than with conventional processes.

“In addition they have advantages during handling, permit higher productivity and do not involve any restrictions during transportation or storage,” says Eisenblätter.

The importance of aerospace

The aerospace sector is of considerable importance for Huntsman, according to the spokesperson. Firstly, the company is active in partnership product development in cooperation with renowned composites manufacturers, and also works together with the major aircraft manufacturers, such as Boeing and Airbus. In addition, there is currently the collaboration in the EU promoted projects ABITAS and PreCarBi.

“The ABITAS project is working on solutions in the structural adhesives sector," she explains. "This is to do with the adhesion of small components that are subjected to high loads. PreCarBi is focusing on the development of new materials, which combine the advantages of carbon fibres and liquid resins.”

For over 60 years, Huntsman has already been a supplier to the aerospace industry. Products include composite resins, tooling materials, syntactic materials, adhesives, laminating systems and electronic materials that can be used for the design, prototype construction and production of aircrafts as well as for servicing. At the COMPOSITES EUROPE 2009 (27-29 October 2009, Stuttgart), the company presents its competencies in this and in other applications of composite materials.

“We will be represented this year for the third time at COMPOSITES EUROPE. Before that we were regular exhibitors and participants during the AVK conference,” Eisenblätter says. "The trade fair provides the ideal platform for Huntsman to meet potential and existing customers. Our interest is primarily directed at visitors from the German speaking region."

Further markets

In addition to adhesives, sealing compounds, coatings, stereo lithography and tooling systems, composites are a major line of business for Huntsman. We offer product solutions for all composite processes from wet lay-up and RTM via infusion up to filament winding and pultrusion. Apart from aerospace, important markets and customers of Huntsman are to be found in the automobile, wind energy, conventional energy, sports and leisure sectors,” she adds.

“Huntsman is the market leader for resin-hardening systems for the composites industry based on epoxy resins, bismaleimide, cyanide tester, benzoxacine and polyurethane systems. We are suppliers of adhesive systems and liquid resin systems for the stated processes, including prepreg manufacture, as well as being a supplier for the formulators with our portfolio for the composites industry,” she concludes. "Where this is concerned, the company offers not only materials but also assistance and technical support for the process application."