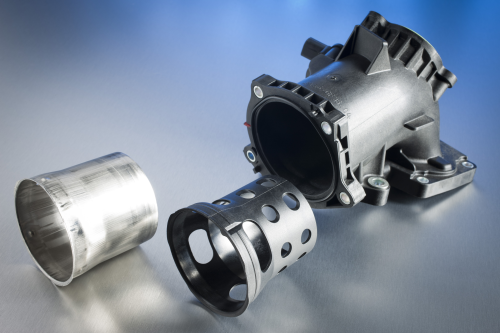

BASF explains that in the air intake region of the charge-air manifold, which features integral exhaust gas recirculation, fresh air and hot exhaust gases are brought together. This is where high mixing temperatures and strong turbulence are encountered. Until now, an aluminium shield provided protection for the wall and a built-in sensor. Now, a heat-resistant plastic insert fulfills this function.

The heat aging resistance of Ultramid Endure comes into play here: The glass reinforced thermoplastic withstands a continuous service temperature of 220°C and peak temperatures of 240°C. This high heat resistance is the result of a stabilisation technology that creates a protective surface layer on the plastic, BASF reports.

In addition, the weight of the plastic part is only half of the previous aluminium part.

| The engine compartment is becoming increasingly compact and thus hotter, BASF reports. At the same time, car makers want to reduce the weight of their vehicles by substituting lightweight plastics for metal. However, high-performance plastics are ruled out because of their high system costs. Ultramid Endure combines exceptionally high heat aging resistance with the good processability of PA 66 – the characteristic that is the determining factor when it comes to system costs, BASF says. The material is thus an ideal alternative for applications around the charge-air system in modern turbocharged engines. |

Two further properties of the thermoplastic composite distinguish the new heat shield from its metal predecessor. Firstly, the plastic functions as a thermal insulator. Additionally, it was possible to incorporate openings in the Ultramid Endure heat shield to produce a specific turbulence in the charge air.

The Daimler engine is the first production application for Ultramid Endure, which was introduced two years ago. There is also a 50% glass fibre reinforced grade ( D3G10), which was introduced last year.(See: BASF introduces thermoplastic composite for engine compartment applications.)