Ultramid Endure D3G10 is resistant to heat ageing up to 220°C and is expected to find applications in engine components such as intercooler end caps and parts in the charge air system of turbocharged engines.

The first member of this new heat ageing-resistant PA family, Ultramid Endure D3G7, has a glass fibre content of 35% and was introduced at the K 2010 plastics trade fair. According to BASF, this product will be found in serial applications soon.

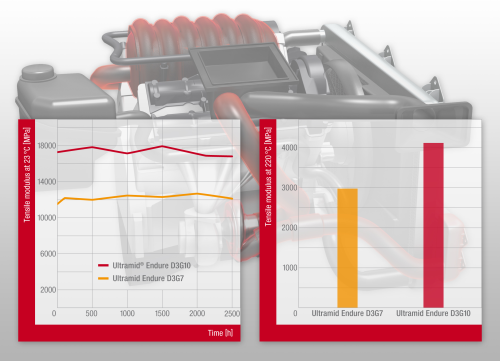

With a tensile modulus of more than 17 000 MPa after ageing (measured in accordance with ISO 527-2/1993), the new D3G10 grade is almost 50% stiffer than the D3G7 version (see graphs).

Over a period of three months (approximately 2200 hours) of heat ageing, the stiffness of the new BASF Ultramid Endure D3G10 remains stable at a high value of about 17 000 MPa (measured in accordance with ISO 527-2 (1993) at 23°C. Prior to the ageing test, the material exhibits a modulus of elasticity of more than 4000 MPa at 220°C, about 30% higher than the less stiff D3G7 product.

BASF claims that compared to high-priced speciality polyamides the use of Ultramid Endure results in a significant system cost reduction.

The Fakuma International Trade Fair for Plastics Processing takes place on 18-22 October 2011 in Friedrichshafen, Germany.