Maine based Ocean Renewable Power Company (ORPC) is the project's developer, owner and operator. ORPC also developed the proprietary technology used.

In August 2011, ORPC and Hall Spars and Rigging entered into a long term agreement for manufacturing and supply of ORPC's Advanced Design Cross Flow turbines using advanced composite materials and manufacturing processes.

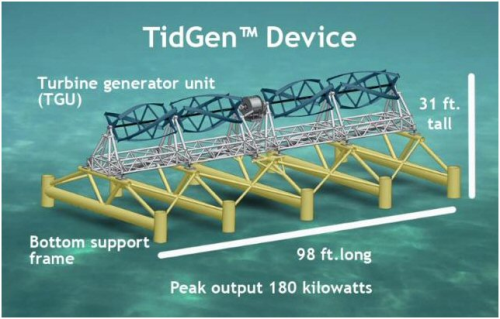

These turbines are key to ORPC’s TidGen™ turbine generator unit (TGU) design. The TGU is the core component or 'engine' for ORPC’s proprietary hydrokinetic device design which captures the energy of moving water without using dams or other barriers.

The first TGU featuring four Hall Spars-made turbines has been installed at ORPC’s project site in Cobscook Bay, Maine.

Drawing from its expertise in designing spars and rigging for high performance superyachts, Hall Spars built ORPC’s turbines with carbon fibre reinforced composites in order to withstand the loads the turbines will encounter and the marine environment in which they will operate.

Hall Spars has three manufacturing locations, in the USA, Netherlands and New Zealand. Recent products include the yachts Wally 50 m Better Place, Reichel-Pugh 85 My Song, Hoek H-Class Firefly, Baltic 72 Stig, Alia 82 Aiyana, and the Ker 50 Varuna. It has also carried out composite projects for the aerospace and defence industries. Hall Spars & Rigging latest initiative is to become a leader in commercial composite projects.

Maine Tidal Energy Project

Established in 2004, ORPC is a privately-held developer of tidal, river and deep water ocean current power generation technology and projects.

The Bay of Fundy, located on the border between eastern Maine and Canada, is one of the most robust tidal energy resources in the world. At its mouth, off of Eastport and Lubec, Maine, ORPC is poised to install its first commercial power systems with the Maine Tidal Energy Project. This three-part project will deploy power systems in Cobscook Bay, at Kendall Head, and in Western Passage, and will be connected to the New England power pool through the Bangor Hydro utility grid.

In 2008, ORPC became the first company to generate electricity from Bay of Fundy tidal currents without the use of dams. A year-long program of in-water testing also proved its prototype turbine generator unit to be a technical success. As the next step towards commercialising ORPC power systems, in 2010 it deployed, operated and tested a beta pre-commercial version of our TidGen Power System, which met or exceeded all technical expectations. This Beta TidGen System was the largest ocean energy device to ever be deployed in the US.

In 2012, ORPC will begin the Maine Tidal Energy Project by installing a commercial TidGen Power System in Cobscook Bay. After running and monitoring this initial system for a year, it will install additional power systems over the ensuing three years to increase the project’s capacity to 3 MW – enough electricity to power 1.,200 Maine homes and businesses.

The Maine Tidal Energy Project is funded in part by the US Department of Energy and the Maine Technology Institute, as well as private investors.