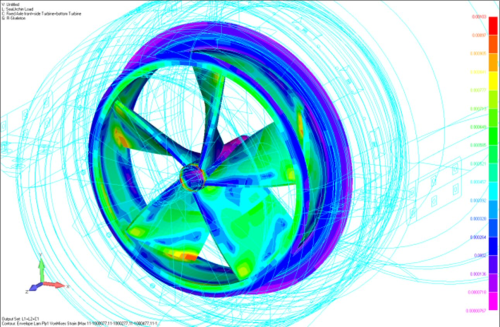

The SeaUrchin is claimed to be as little as half the cost of competing marine generators to manufacture, install and maintain. The turbine generates electricity by harnessing the kinetic energy from free-flowing ocean streams, tides and flowing rivers. No dams or barrages are necessary, thus reducing environmental impact.

The turbine was developed by Elemental Energy Technologies Ltd (EET), based in Sydney, Australia.

| The long-term cost savings resulting from our choice of state-of-the-art composite materials will result in cheaper electricity despite the harsh environment that SeaUrchins will operate in. |

| SeaUrchin's designer Michael Urch |

The prototype 2 kW SeaUrchin currently being tested is about 1.2 m long with an overall diameter of approximately 1.1 m. A feasibility study has been finalised for a 1 MW utility-scale turbine which is approximately 15 m long and 9.5 m in diameter at the intake.

All of the structural elements are made out of composites, with only the electrical, shaft and bearings of other materials.

RPC Technologies, an Australian designer and manufacturer of composite components, was in charge of researching and advising on the composites utilised in the turbine.

For further information about the SeaUrchin's design and composite construction see: SeaUrchin: the future is tidal.