SeaGen is believed to be the first commercial system in the world capable of collecting energy from tidal or other marine currents. It is four times bigger than any other tidal project so far built, including MCT's own 300 kW Seaflow system installed off Lynmouth, UK, in 2003.

SeaGen is sited roughly 1 km south of the ferry route between Strangford and Portaferry, approximately 400 m from the shoreline. When fully operational later this year, it will operate for up to 18-20 hours per day to produce electricity equivalent to that used by 1000 homes.

Aviation Enterprises Ltd, Lambourn, UK, was responsible for manufacturing the blade assemblies. The company, a design, development and manufacturing organisation specialising in the light aviation industry and the application of composite materials, also designed and installed a fibre-optic stress sensing system into the blades to monitor their performance. Advanced Composites Group (ACG)'s VTM®266 prepregs were selected for the manufacture of the 65 mm thick structural spars, the elements that add strength and rigidity to the two 8 m long blades.

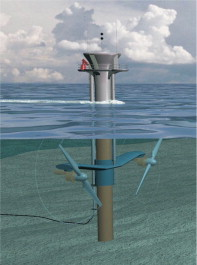

The SeaGen technology consists of twin axial flow rotors of 15-20 m in diameter (the size depending on local site conditions), each driving a generator via a gearbox much like a hydro-electric turbine or a wind turbine. The turbines have a patented feature by which the rotor blades can be pitched through 180° in order to allow them to operate in bi-direction flows – on both the ebb and the flood tides. The twin power units of each system are mounted on wing-like extensions either side of a tubular steel monopile some 3 m in diameter and the complete wing with its power units can be raised above sea level to permit safe and reliable maintenance.

The base of SeaGen's structure, which sits on the seabed, is currently being installed. Each of the four pins that secure the structure will be drilled to a depth of about 9 m. This will be followed by a commissioning phase to connect the tidal system up to the local electricity network for commercial use. ESB Independent Energy, the retail subsidiary of Ireland's ESB generating utility, has offered a Power Purchase Agreement to supply its customers on the island of Ireland with electricity from SeaGen.

MCT has established a £2 million programme to closely monitor the environmental impact of the SeaGen turbine.

In February, MCT announced a joint initiative with electricity supplier npower renewables to take forward a 10.5 MW project using several SeaGen devices off the coast of Anglesey, north Wales, UK. It is hoped the tidal farm will be commissioned around 2011-2012.

“There is global interest in SeaGen as it will be the largest commercial tidal stream device to be installed anywhere in the world, so we can expect its installation to be a springboard for the further development of the marine energy industry in the UK and the island of Ireland,” says Martin Wright, Managing Director of MCT. “Looking ahead, MCT intends to manufacture and deploy a series of SeaGen devices in projects off Anglesey, UK, and on the Canadian seaboard within the next 2 to 4 years.”