Specialist composite prepreg producer GMS Composites has developed a flame retardant (FR) epoxy prepreg with increased toughness and a shorter gel time.

The new FR grade, GMS EP-540, is a non-halogenated epoxy resin matrix prepreg, replacing EP-530, a previously developed FR grade which had an average 16 minute gel time at a 120ºC mold temperature.The new grade has a faster gel time down to 6 minutes at 120ºC for thinner laminates, with parts fully cured within two hours. The material is suitable for motorsport OEMs as well other sectors needing high FR rated prepregged composite parts, such as powerboat racing, aerospace, defence, rail and hazardous goods vehicles. The FR epoxy prepreg can also be tested fr for carbon fiber composites parts in GT3, GTE, rally cross and similar racing car classes

The prepreg also passes the UL94 V0 flammability rating. The UL94 standard rates the ignition characteristics of plastic materials. To achieve the highest V0 flammability resistance rating for UL94, test samples are placed vertically with a specified test flame applied from below directly on the bottom of the sample; all flaming combustion must extinguish within 10 seconds, and without burning to the top clamp or dripping molten material.

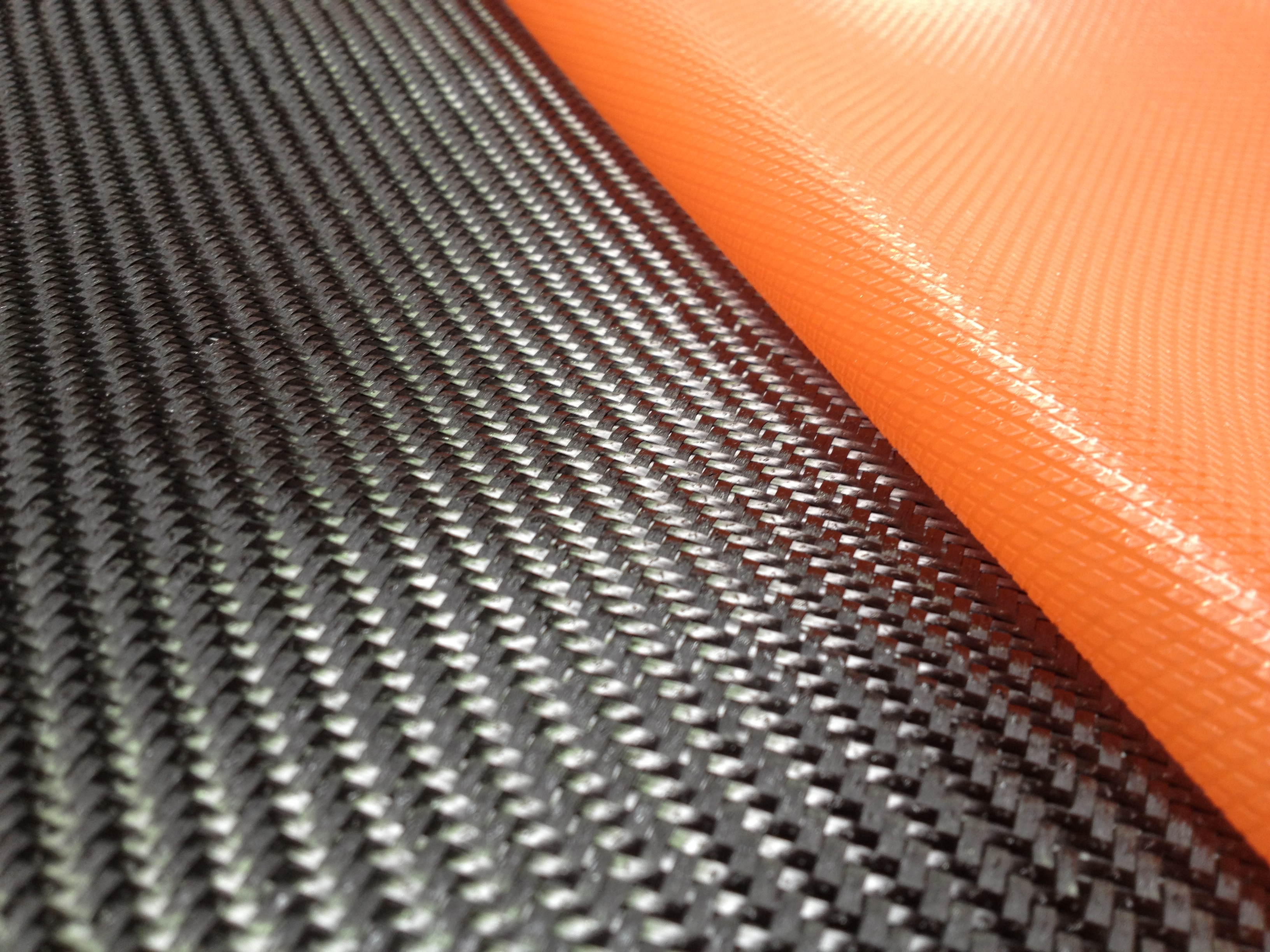

Resin formulation According to GMS Composites test data, the EP-540 epoxy prepreg has a tensile strength of 460 MPa, flexural strength 578 MPa, with an Izod Impact strength of 230 J/m. Fire performance data provided shows that the UL94 V0 rating is achieved in the vertical flame test, recording an average burning time of three seconds, seven seconds less than the maximum allowable combustion time to meet the V0 rating, and two seconds less than the old EP-530 grade it replaces. The resin formulation of GMS EP-540 suit a range of cure cycles, pressures and ramp up rate options possible depending on the part being produced, and the tack can also be varied. The curing cycle for GMS EP-540 ranges from 80ºC to a maximum of 150ºC. The grade is compatible with all standard sandwich core materials, as well as carbon, glass and aramid fiber reinforcements. GMS EP-540 prepreg has a shelf life in excess of six weeks at a 23ºC ambient temperature and 12 months in -18ºC cold storage conditions. All GMS Composites prepreg resins are manufactured to ISO 9001:2008 accredited quality assurance systems and procedures at its main factory in Melbourne, Australia.

This story is reprinted from material from GMS, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.