Discovery Yachts, located at Marchwood, near Southampton, UK, switched from traditional wet lay-up to infusion for the Discovery 57 to improve the quality and performance of the yacht, to reduce styrene emissions and improve shop floor working conditions.

To develop the production skills required to confidently infuse sandwich laminate parts as big as a hull, the Discovery Yachts composites team undertook several months of trials. It worked in close collaboration with its suppliers:

- Scott Bader, for the resins and gel-coat;

- Gurit for the core material; and

- Composite Integration Ltd for the vacuum infusion pumps, mixing and dispensing equipment.

Hull production

The Discovery 57 hull is 57.3 ft (17.4 m) long, with a beam of 16.67 ft (5.1 m) and a 7.67 ft (2.35 m) draft. It was infused using vacuum bagging in one complete section to precise dimensions and a ‘pre calculated’ 500 kg lower composite hull weight. The infusion process has produced a better consolidated laminate, making a stronger yet significantly lighter hull for improved speed; the 500 kg saving is a 20% weight reduction.

The hull is manufactured using Scott Bader’s Crystic® VE 679-03 vinyl ester resin in combination with a ‘matched’ marine system using Crystic VE 679PA skincoat and Crystic Permabright D-Iso/NPG high performance gel-coat.

“When we started looking at infusion, we wanted to find a suitable supplier with matched products for the entire system: gel-coat, skincoat and vinyl ester infusion resin," says Discovery Yachts production director Ben Collett. "We looked at a number of options, but Scott Bader was an easy choice even though they had not supplied vinyl ester resins to us before.”

The production of the hull starts with the application by hand of the Crystic Permabright gel-coat and then the Crystic VE 679PA skincoat. The addition of a skincoat provides a gel-coated laminate with optimum osmotic blistering resistance and improved gel-coat aesthetics.

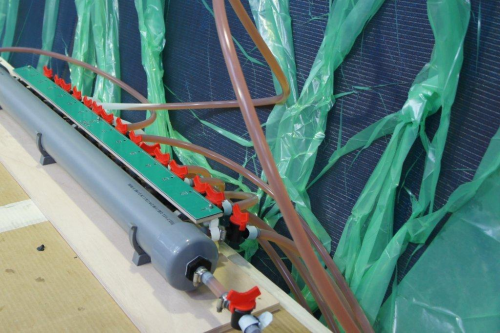

Next, the reinforcement fabrics and Corecell™ M-Foam core material were placed in the mould, followed by a peel ply and a flow mesh. Finally the resin lines were laid on the flow mesh and the vacuum bag was placed over the top and sealed to the mould. To mould the 57 ft hull in one shot several manifolds were needed for the numerous vacuum lines and resin lines.

As well as the Discovery 57 hull, Discovery Yachts now also produces various internal structural components and floor trays usinv the vacuum infusion process. It is also planning to start infusing complete decks later this year.

The Discovery 57 will debut at the Southampton Boat Show in September 2012.