The Revolver 42 was constructed by Italian shipyard Anselmo Mauri, located in Sirmione, Lake Garda.

The Revolver 42 design is a collaboration between US speedboat hull designer Michael Peters Yacht Design, whose designs have won over 200 Offshore Class 1 races worldwide, and Milan-based studio H3O, which carried out the interior design and all concept engineering.

The boat is 12.6 m long and 3.4 m wide, with a dry weight of 7500 kg. It can reach speeds of up to 68 knots.

H30 worked closely with Resintex Technology Srl, based in Frosinone, Italy, to specify the best combination of composite materials for the boat. They opted for a sandwich laminate structure for the main hull and deck, vacuum infused using Scott Bader's Crystic® vinyl ester resins and a Gurit Corecell™ M-foam core, with carbon fibre used at major load points on the hard top.

To further reduce weight, the hull bulkheads were bonded with a Scott Bader Crystic Crestomer® structural adhesive.

Vacuum infusion

Resintex recommended vacuum bagging as the best infusion process to produce the hull and deck fibreglass sections as vacuum infused laminates are significantly lighter compared to hand layup, while also providing higher mechanical properties.

To provide a tough, marine approved laminate construction for the hull and deck, Scott Bader’s Crystic VE679-03PA infusion grade low shrink DCPD modified vinyl ester resin was specified in combination with a ‘matched system’ Crystic VE679PA skincoat. Scott Bader developed DCPD modified vinyl ester resins and skincoats to provide the mechanical performance needed for marine applications, while also reducing print through to improve the aesthetic finish of the gel-coated surfaces of visible fibreglass parts.

To help minimise the overall weight of the Revolver 42, carbon fibre fabrics were used to reinforce the points of maximum loading in the cockpit hard top. Other critical performance areas subject to very high stresses and loads in the superstructure, such as the slamming area of the hull, were designed with a foam cored sandwich structure. Marine approved Corecell M-Foam DC core material, which is manufactured by SP-High Modulus, the marine business of Gurit, was specified for the infused hull and deck sandwich constructions.

Structural adhesive

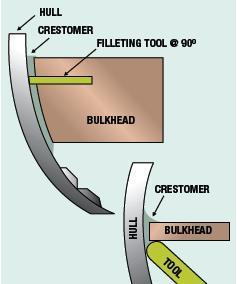

To make further reductions in the hull weight of Revolver 42, while at the same time improving the overall mechanical performance of the hull construction, Resintex Technology also recommended Scott Bader’s Crystic Crestomer 1152PA urethane acrylate structural adhesive to bond structural bulkheads in the hull.

By using Crestomer 1152PA instead of over laminating, Revolver 42’s hull weight was reduced by over 45%.