Lanxess has developed a new composite made from natural flax fibers and bio-based polylactic acid as part of its Tepex range of continuous-fiber-reinforced thermoplastic material.

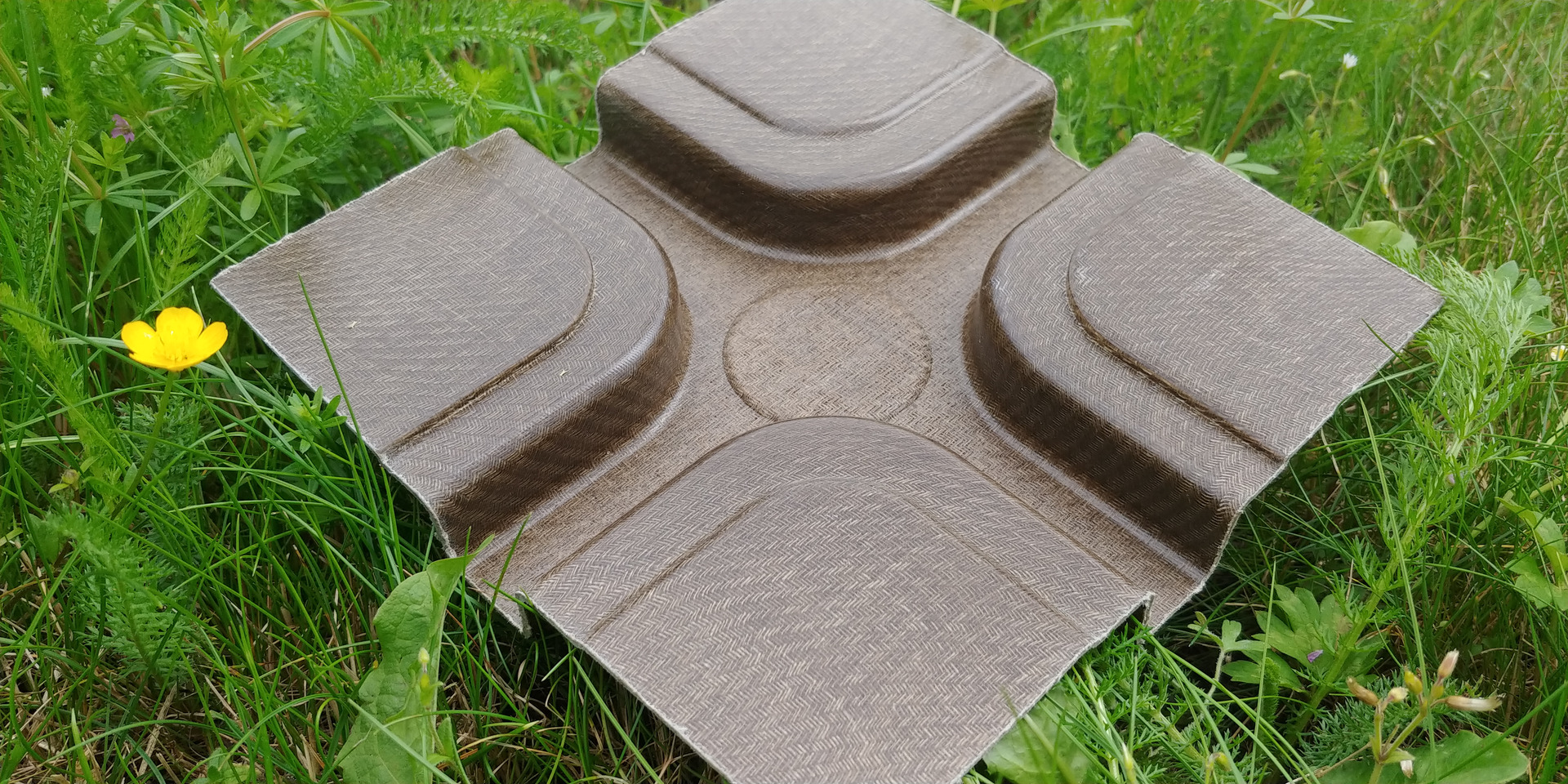

According to the company, flax fibers have a lower density than glass fibers, and so composites made with these fibers are lighter in weight than their glass fiber reinforced counterparts. When coupled with transparent matrix plastics such as polylactic acid, the reinforcing flax fabric yields surfaces with a brown natural carbon fiber look.

‘We have combined fabrics made from s a matrix material and thereby developed a composite manufactured entirely from natural resources,’ said Dr Stefan Seidel, head of research and development. ‘We are now able to produce it to a level of quality suitable for large-scale production.’

Lanxess says that the biocomposites can be completely recycled as purely thermoplastic systems as part of closed-loop material cycles. ‘Offcuts and production waste can be regranulated and easily injection-molded or extruded, either alone or mixed with unreinforced or short fiber reinforced compound new materials,’ said Seidel.

This story uses material from Lanxess, with editorial changes made by Materials Today.