Ensinger, which makes composite materials, has reportedly added three new materials to its continuous fiber-reinforced thermoplastic plates for industry.

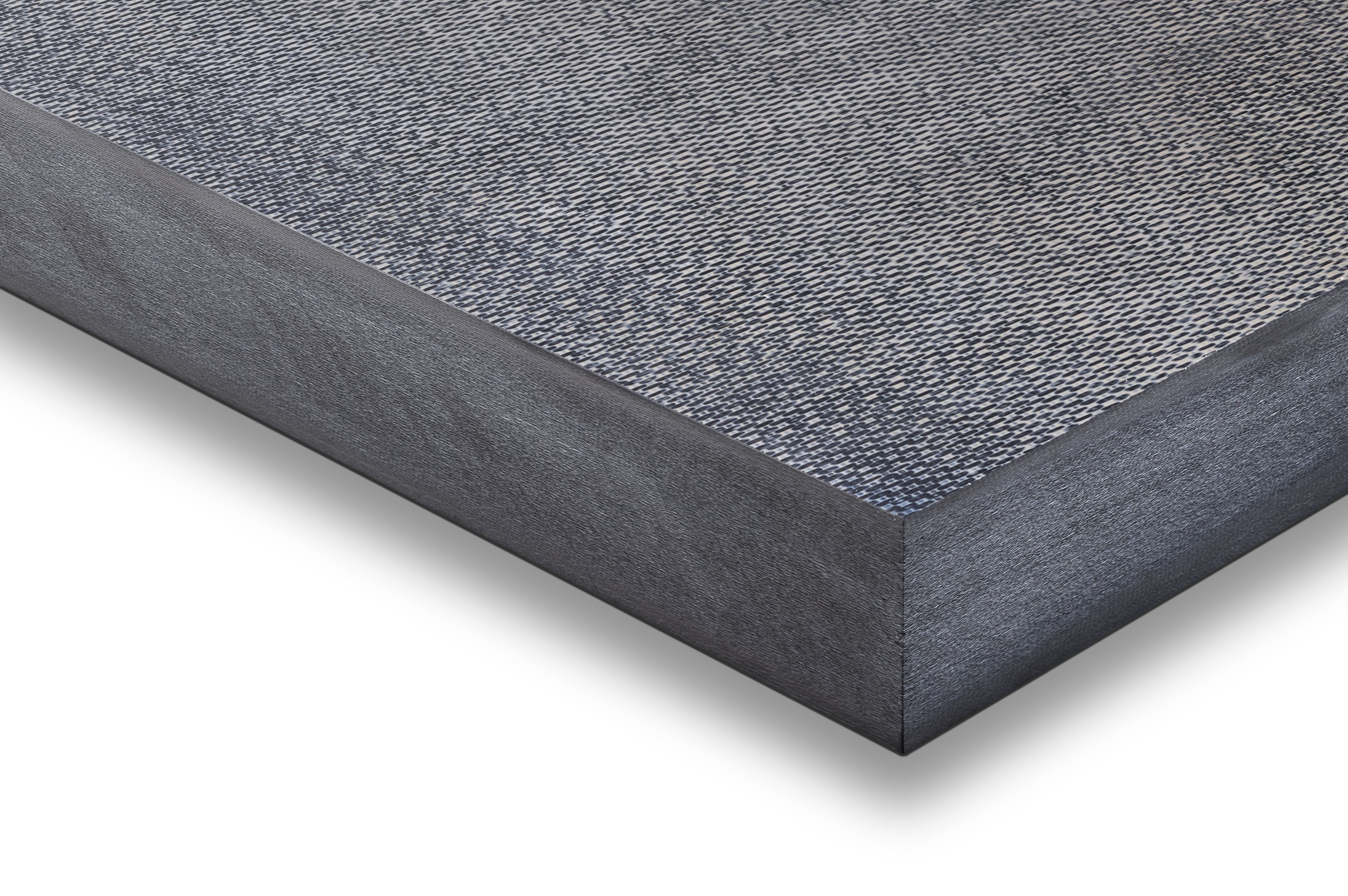

According to the company, the plates are suitable for applications where the mechanical requirements are too high for unreinforced or short fiber-reinforced plastic stock shapes, with the continuous fiber reinforcement imparting mechanical properties similar to metallic materials at a lighter weight.

Ensinger says that due to the thermoplastic matrix materials, the plates also have high impact strength, constant properties over a broad temperature range, chemical resistance and high elongation at break.

The new materials are TECATEC carbon fiber reinforced polyphenylene sulfide (PPS) CW50 black, which has improved temperature and chemical resistance, and dimensional stability over a broad temperature and humidity range; TECATEC glass fiber reinforced polyetherimide (PEI) GW50 natural which has a continuous service temperature of 170°C, good electrical insulation and gire, smoke and toxicity retardance (FST); and TECATEC carbon fiber-reinforced polycarbonate (PC) CW50 black which has a transparent matrix and high impact toughness.

The new composite plates have densities between 1.5 and 1.8 g/cm3 and have coefficients of thermal expansion (CTE) in a range around 5x10-6 K-1. They can also be produced to bespoke requirements with maximum dimensions of 525 x 625 mm and thickness between 0.5 to 95 mm.

Ensinger says that the plates are suitable for the aerospace industry, mechanical engineering, the automotive industry and the sports equipment sector, and for the manufacture of prototypes and small batches.

This story uses material from Ensinger, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.