Michelman says that it has launched a new carbon fiber sizing product, as part of the company’s Hydrosize water-based range. Hydrosize Carbon allows carbon fiber manufacturers to improve the interfacial adhesion between the polymers and the fibers by tailoring the surface chemistry of their reinforcement fibers to the chemistry of the matrix resin.

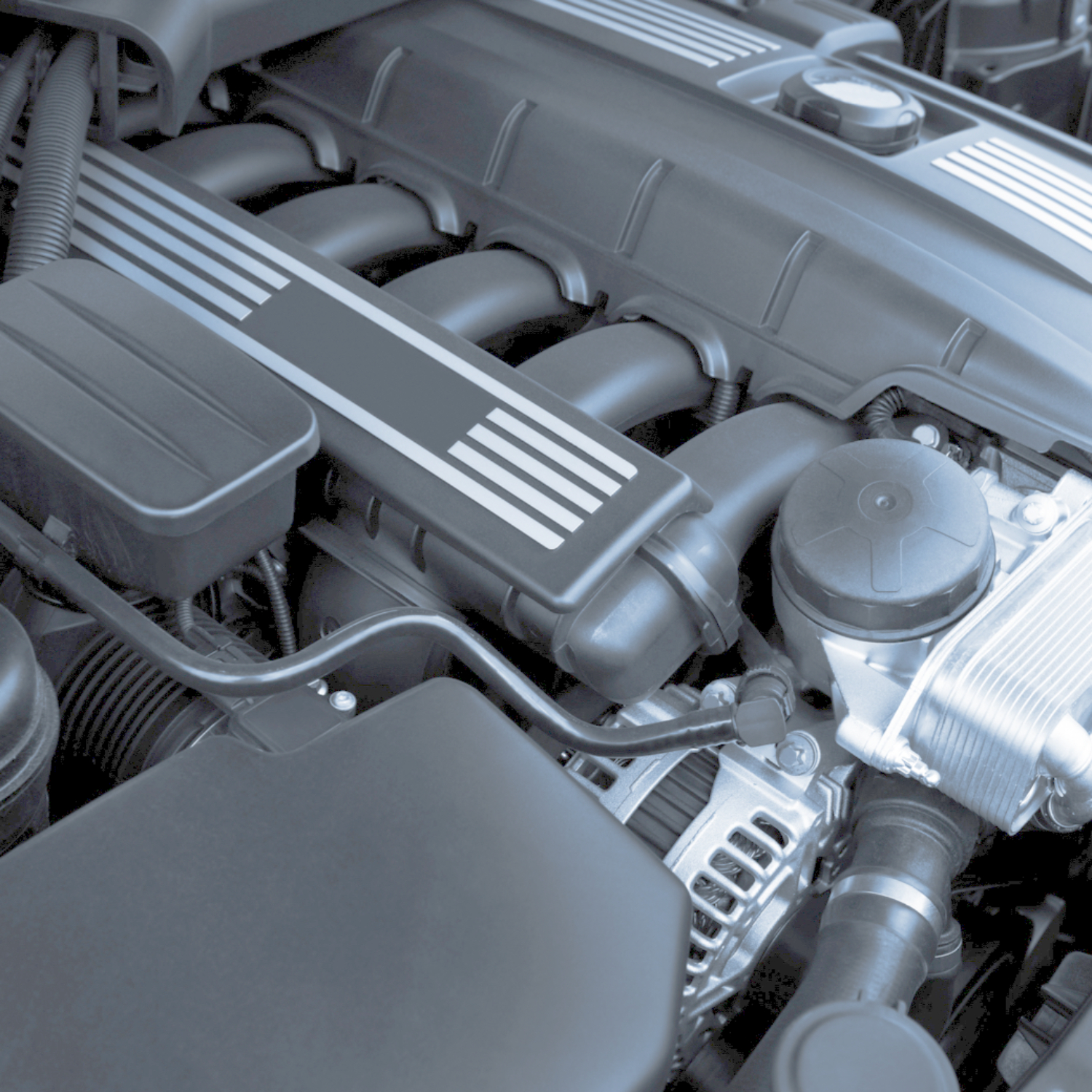

The Hydrosize Carbon 200 Series has been designed for polyamides including high-temperature application. It is alkyl phenol ethoxylate (APE), solvent, and volatile organic compound (VOC)-free and is suitable for fiber reinforced nylon composites where greater thermal stability is required. The 300 Series has been formulated for polycarbonates (PC) and other PC blends such as PC- acrylonitrile butadiene styrene (ABS), and reportedly has improved chemical resistance and interfacial adhesion to polymer systems. Applications include laptop cases or other electronic components. The Hydrosize Carbon 400 Series includes grades that can withstand more extreme processing temperatures and can work with materials include polyaryletheretherketone (PEEK), polyphenylene sulfide (PPS), polyethylenimine (PEI) to produce various composite engine components. It is suitable for use with chopped carbon fiber applications. Michelman’s Carbon 700 Series has been designed to improve the performance of carbon fiber reinforced vinyl ester composites and is suitable for under-the-hood applications. It can provide increased adhesion between the carbon fiber and various vinyl ester compounds.

This story uses material from Michelman, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.