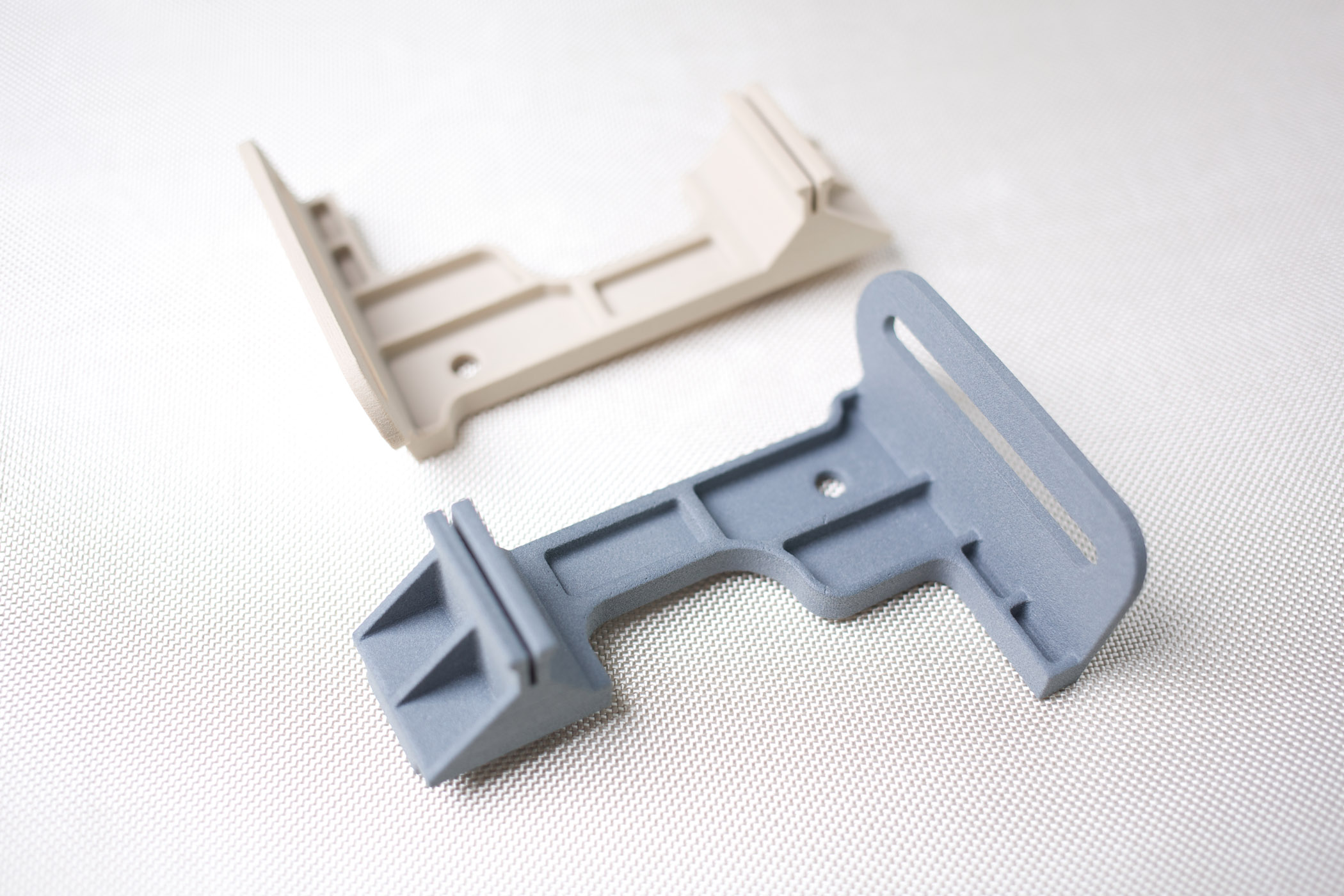

Polymer specialist Victrex and the University of Exeter in the UK have commissioned a new 3D printer to process the company’s polyaryletherketone (PAEK) polymers and composites.

The organizations also plan to use the EOS P 810 laser sintering platform to improve the performance of underlying additive manufacturing (AM) processes at the Centre for Additive Layer Manufacturing (CALM) at the university.

‘We can now further our research by utilizing the next generation of high temperature systems, the EOS P 810,’ said Professor Oana Ghita, CALM lead of at the niversity. ‘The new equipment allows us to link the fundamental research with the commercial manufacturing process, to optimize the materials and their application, while accounting for the new thermal, optical, and mechanical upgrades and providing us with accurate insights into the detailed dynamics of laser sintering.’

The printer can process materials with melting temperatures around 300°C (572°F) and is also suitable for low-melting-point PAEK polymers designed by Victrex.

This story uses material from Victrex, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.