Additive manufacturing (AM) specialist EOS has launched a new 3D printer specifically designed to process its new carbon-fiber reinforced material, HT-23.

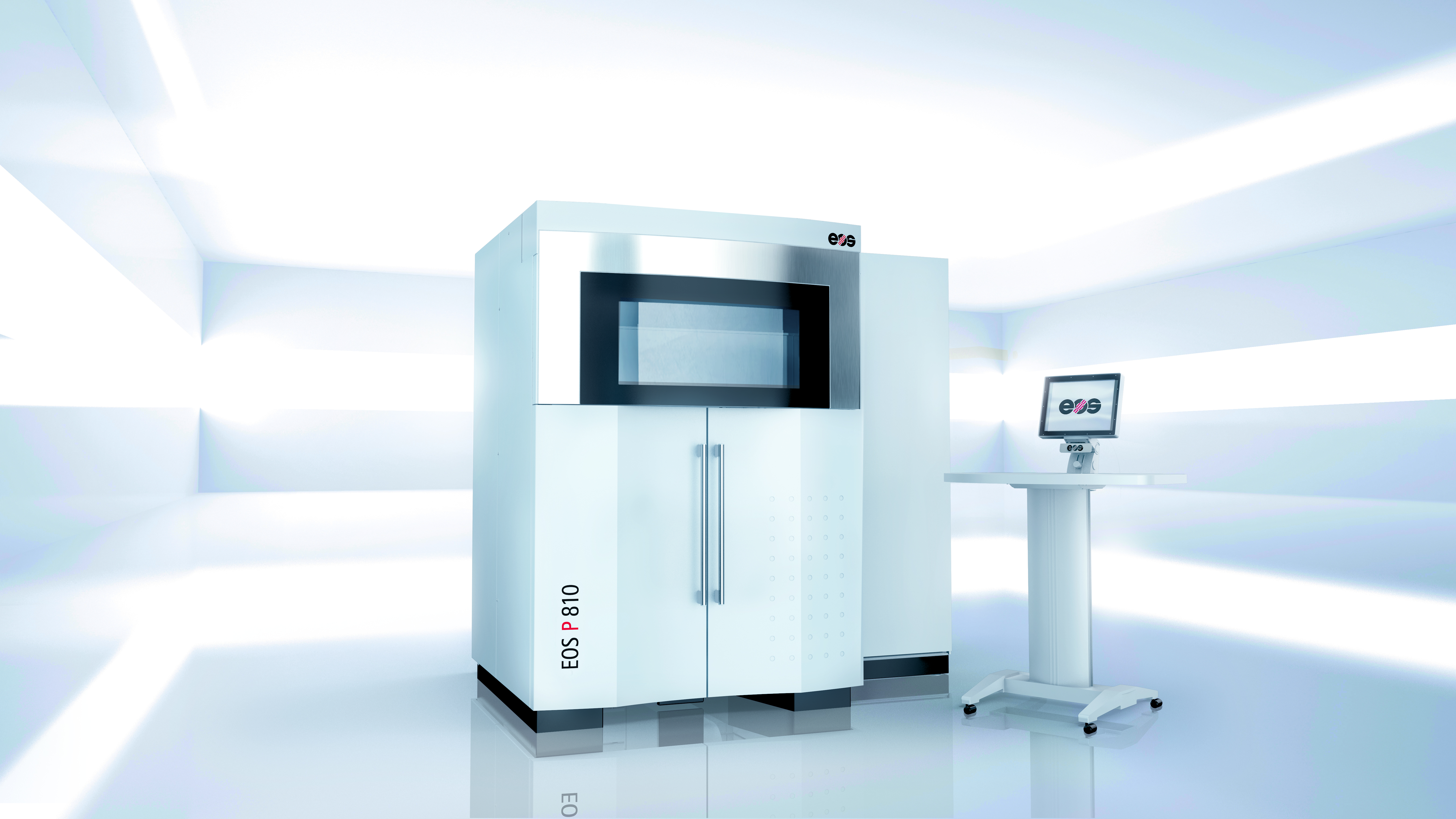

EOS P 810 has been developed with Boeing for the aerospace industry but can also be applied for other industries. It is based on the EOS P 800 and has a build volume of 700 x 380 x 380 mm and two 70 Watt lasers. It is particularly suited for industrial applications, EOS says.

‘The aerospace industry has to meet challenging requirements when it comes to UV resistance, flame retardancy and meeting Federal Aviation Regulations (FAR),’ said Scott Killian, aerospace business development manager at EOS. ‘Additive manufacturing enables the design and manufacturing of complex geometries without expensive tooling. This allows aerospace OEM's to replace composite parts which to date are being produced manually via carbon fiber laminating. They can also replace aluminum parts with HT-23 while still meeting the material strength properties required for the application.’

HT-23 is reportedly the first carbon fiber-reinforced PEKK material that can be processed on EOS systems. Parts additively manufactured with this material offer high strength, low weight and are capable of withstanding high temperatures. It is reportedlt the first material with a low refresh rate of 40%.

Weight reduction

‘Our EOS P 810 polymer 3D printing platform and the ALM HT-23 material enabled us to help Boeing reach high demands for weight reduction, cost efficiency and reduced assembly time for components,’ said Killian. ‘The technology platform addresses Boeing's needs and allows them to achieve homogenous part properties within the overall building volume, a key factor for cost efficient manufacturing of air ducts, small turbines and holders.’

The material is also suitable for applications such as plugs or housings, serial parts and spare parts for the interior and exterior (exterior facing) of busses and trains. Parts made of HT-23 fulfil the regulation EN 45545.

This story uses material from EOS, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.