The new roving, SE4535, is commercially available globally and complements 3B's existing SE4220 product for LFT polypropylene (PP) composites.

3B is committed to be a major player in LFT reinforcements.The Belgium headquartered company reports that the market for LFT has experienced strong growth in recent years, with demand led by the automotive industry. Although polypropylene (PP) resin dominates the LFT market at present, there are opportunities for alternative polymers such as polyamide (PA) in more demanding applications.

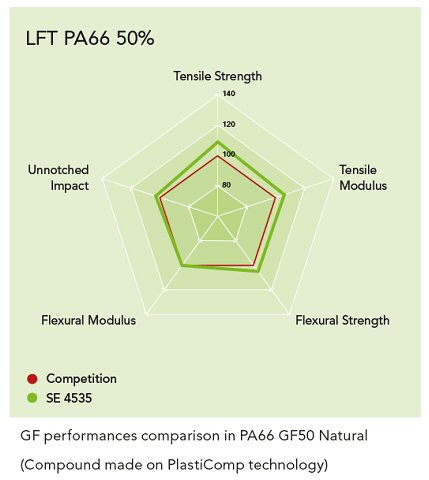

“Resin differentiation, mainly through polyamide, clearly opens new opportunities, as in engine mounts, crash absorbers, seat structure inserts and safety parts," explains Eric Martin, Business Development Leader at 3BT. "To pursue LFT penetration into these more challenging applications, 3B fully demonstrates its ability to provide reliable cost competitive leading-edge reinforcement solutions, such as the new SE 4535 grade.”

3B’s new SE4535 roving features a proprietary sizing chemistry which is specifically engineered to provide excellent wet out, optimum resin-fibre load transfer and adhesion for exceptional mechanical performances.

“Excellent impregnation and high speed processability make it suitable for all LFT processes (G-LFT, D-LFT, etc)," reports Paul Cazes, Thermoplastic Product Leader at 3B.

The 3B SE4535 roving is available in 17 µm at 1200 tex (SE4535 17 1200) and 2400 tex (SE4535 17 2400). It is manufactured from Advantex® glass fibre which combines the electrical and mechanical properties of traditional E-glass with the corrosion resistance and durability of an E-CR glass.

3B will continue to expand its LFT reinforcements’ portfolio to meet emerging market requirements, Cazes adds.