Over the past 35 years the glass fibre reinforced plastics (GRP) industry, together with the unsaturated polyester resin producers, has put a huge amount of effort into reducing exposure to styrene. But up until now, a study has never been carried out into how successful these efforts have been. The Association of Plastics Manufacturers in Europe (PlasticsEurope), based in Brussels, Belgium, therefore commissioned Industox Consult in the Netherlands to review available data on styrene exposure in the European GRP industry over the last 35 years. The result was a database with more than 34 000 styrene exposure measurements from the industry covering the period 1967-2002.

Statistical analysis of the data shows that time, region and job category are strong predictors of styrene exposure. The data also show that efforts to lower occupational styrene exposure have been very effective, as the following findings show:

- Styrene exposure in the open mould sector of the GRP industry has fallen by an average of more than 3% per year over the last 32 years. This annual decline appears to be higher in the Nordic region than in the countries in the southern parts of Europe.

- Mean styrene concentrations in the 1970s and early 1980s could occasionally range up to about 150 ppm (approximately 650 mg/m3). In the 1990s the average styrene exposure of open mould workers in Europe was significantly lowered to 12-60 ppm (50-250 mg/m3).

- Whereas a styrene monomer content in the resin of about 40-45% was normal 30 years ago, nowadays standard resins contain around 35% styrene and in some cases even less.

Styrene

Styrene is the ideal monomer used for cross linking unsaturated polyester resins. Although alternative monomers have been extensively investigated but none can, on a broad scale, match the performance of styrene. A small part of the styrene monomer evaporates during processing into the atmosphere.

Reducing worker exposure to styrene monomer has been a central focus of attention for the composites industry over recent decades.

Responsible care

Over the last 30 years the awareness of the polyester processing industry concerning the effects of exposure to styrene has steadily increased. More information has become available about the health issues concerning styrene exposure and the industry has acted responsibly by pursuing strategies to reduce exposure levels.

In many European countries programmes have been under way for quite a long time to lower the styrene exposure in the polyester industry and many of these programmes were either supported or enforced by national legislators.

Advances in resin technology

At the same time, the resin industry quickly set about the task of developing low styrene emission (LSE) resins. The addition of LSE additives to the resin significantly reduces the emission of styrene, especially during the static phase of open mould processing.

As a result of the wax present in the additives, early LSE additives led to delamination problems, particularly in applications where the glass fibre reinforced laminates were subjected to high mechanical forces. Nowadays LSE resins are widely used in open moulding; the formulations have been greatly improved and the quality and value of LSE resins is undisputed.

Other resin types were introduced, such as resins based on dicyclopentadiene (DCPD) as a raw material, which results in a slightly lower styrene content compared to standard unsaturated polyester formulations.

By modifying the molecular backbone of a resin, it is possible to reduce the styrene content further and developments continue into improved, lower styrene content resins. Whereas a styrene content of 40-45% was normal around 30 years ago, nowadays standard resins contain around 35% styrene monomer.

In certain cases resin formulations have been developed with a styrene monomer content as low as 20%, but the processing of these resins is more complicated, which reduces the possibilities for their more widespread use.

Low styrene technologies have substantially reduced emissions in both the dynamic and static moulding phases.

Advances in processing technologies

Technological advances have brought new closed moulding techniques, such as vacuum resin infusion, that significantly reduce emissions of styrene.

In addition to these environmental advantages, closed mould techniques mean added benefits in terms of improved consistency, mechanical properties, surface quality and production speed. Closed moulding is therefore becoming more widespread, especially in industries such as boat building, where large hull and deck moulds are used.

Open mould techniques, like hand lamination and spray-up, still retain a prominent place in the processing of unsaturated polyester resins, but the shift to closed moulding is gaining momentum all the time as technologies improve and legislative pressure grows. In 2002, approximately 53% of the resin volume was used in open mould applications and 40% in closed mould applications.

Legislation

Legislation concerning the use of chemicals, in general has certainly triggered more focus on the occupational exposure to styrene in the polyester industry. In each European country TLV (threshold limit value) or MAC (maximum acceptable concentration) values are set for styrene.

30 years ago TLVs were between 50-100 ppm. Today, TLVs are between 20 ppm and 100 ppm, although many countries have brought them down to a level of 20-25 ppm.

On a European scale, styrene is subject to a risk assessment procedure according to European Regulation 793/93. In the framework of this regulation existing high volume chemicals have to be risk assessed – a procedure that has led to a much greater understanding of the toxicological profile of styrene. The risk assessment report is expected to be finalised early 2008.

Study procedure

As part of the Industox study into worker exposure to styrene, different sources were used to collect data. Relevant peer-reviewed scientific articles and reports available at PlasticsEurope and from other industrial sources were collected and a search was conducted into literature databases, such as MEDLINE and TOXNET, between June and September 2005.

A total of around 60 publications and reports were found to contain usable data on styrene exposure of workers in the European GRP industry. Styrene exposure data from databases in Europe, for example NSDB-UK, MEGA-Germany (updates until 2002), PlasticsEurope (six European countries), Norway, Denmark, Finland and France (as far as they are published) were included in the study.

All the publications and reports were screened by experienced industrial hygienists for information on the following parameters:

- type of styrene measurement (air samples, urine metabolites and blood samples);

- year and country of measurement;

- job category;

- use of personal protective equipment (PPE);

- workplace ventilation; and

- various other variables, such as resin type, sampling strategy, and purpose of study.

The air measurements were divided in short term measurements, where the sampling period was 1 hour or less, and long term measurements with a sampling period of more than 1 hour (frequently a full 8-hour work shift).

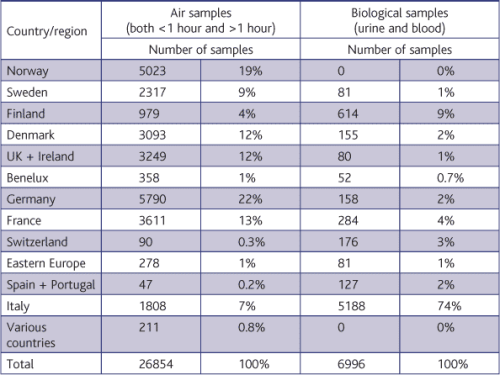

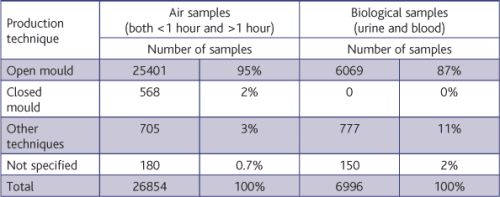

Overviews of the retrieved data covering the period 1967-2002 are presented by country in Table 1 and by production technique in Table 2. It should be noted that more than 95% of the retrieved mean styrene concentrations are long-term measurements and a large majority of the retrieved biological monitoring data are styrene metabolites – mandelic acid and/or phenylglyoxilic acid, in urine. The measurement of styrene in blood is not very common – less than 5% of all the biological samples.

Most of the retrieved air sampling data are from the Nordic countries and the middle region of Europe. Italy, especially, uses biological monitoring to assess occupational exposure to styrene. The majority of the retrieved data on air samples come from companies that use open moulding techniques (95%).

Comparison of the estimated use of polyester resin in the various countries in Europe in 2002 with the retrieved styrene exposure data, indicates that the database contains a lot of styrene exposure data from the Nordic countries but very limited exposure data from Spain and Portugal. Data on styrene exposure of workers applying closed mould techniques are limited in comparison to the amount of resins used for these techniques.

It should be pointed out that the retrieved exposure data probably tend to overestimate the true styrene exposure in the GRP industry. A substantial part of the collected styrene exposure data are from national databases of various European countries. Many of these data are collected in cases where perceived problems with high exposures have occurred. There are strong indications that exposure data from companies and/or workers in the GRP industry with relatively high exposures are therefore over-represented in these databases.

In addition, data retrieved from peer-reviewed scientific literature are mostly data collected during studies/surveys into possible adverse health effects in relation to styrene exposure. Although these studies hardly contain information on the sampling strategy, it is likely that, in many instances, a sort of ‘worst-case’ strategy is followed. Bear in mind that, in order to compare the incidence of possible adverse health effects with non-exposed control persons, researchers of adverse health effects generally tend to select both companies and workers where they can expect relatively high exposures for their surveys. It is therefore likely that these ‘worst case’ measurements are over-represented in the Industox study.

The open mould industry

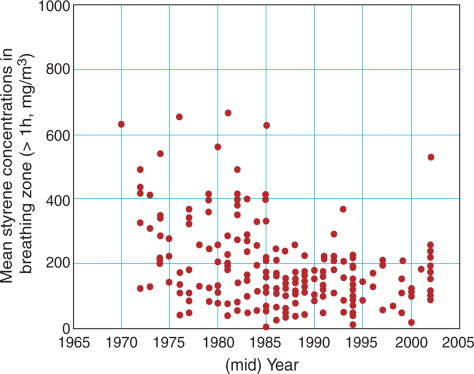

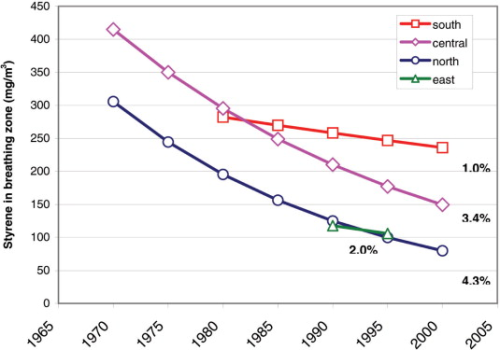

The styrene exposure data in the open mould industry, measured by long-term air samples are presented in Figure 1. It should be noted that the figure represents all the retrieved mean styrene concentrations in the breathing zone air of open mould workers from across Europe.

The figure shows that reported mean styrene concentrations in the 1970s and early 1980s ranged up to about 150 ppm (650 mg/m3). In the 1990s the average styrene exposure of open mould workers in Europe is significantly lower at 12-60 ppm (50-250 mg/m3).

Biological monitoring

Measurements of the concentration of styrene in the working atmosphere are not a good indicator of the internal exposure of workers, particularly in cases where personal protection equipment such as breathing masks are used. Urine and/or blood measurements give a better picture of what is called the ‘internal dose’ of the workers.

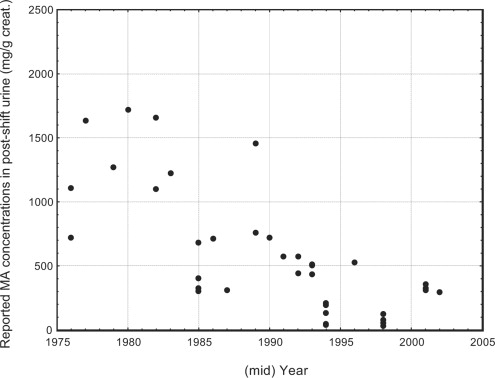

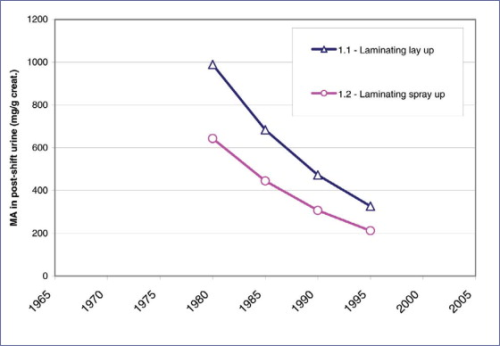

The retrieved data on urinary mandelic acid, a styrene metabolite, are presented in Figure 2. This graph shows a steep decline in urinary styrene metabolites in open mould workers during the last 35 years.

It should be noted that the study was not able to retrieve biological monitoring data from workers using closed mould techniques.

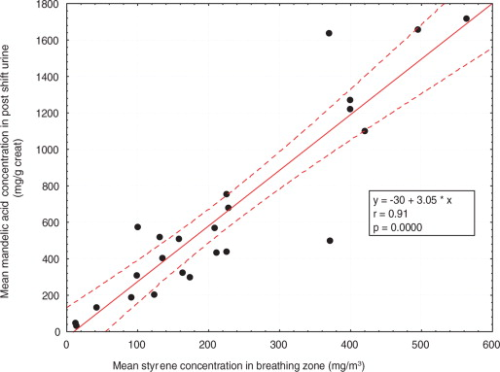

In a number of cases the study had access to combinations of air measurements and biological monitoring data, which made it possible to establish the correlation between these different monitoring methods. Figure 3 presents the data of the combined styrene measurements in the breathing zone and mandelic acid (MA) in post-shift urine measurements, and regression analysis of the reported mean values shows a highly significant correlation.

This figure shows that an exposure to a time-weighted average of 20 ppm styrene in breathing zone air (approximately 87 mg/m3) equates with a concentration of mandelic acid in post-shift urine of 234 mg/g creatinine.

Trend analysis of exposure data

A time trend analysis was carried out on the available observations of styrene in breathing zone (>1 hour) and mandelic acid in post-shift urine samples of open mould workers, by applying so-called linear mixed models. Given the fact that analyses were performed on aggregated data, a weighted analysis was done with the number of observations as weighting unit.

A total of 213 arithmetic mean values were divided across the four regions in Europe:

North

- Norway

- Sweden

- Finland

- Denmark

Central

- UK + Ireland

- Benelux

- Germany

- Switzerland

East

- Countries classified as ‘Eastern Europe’ (Poland, Hungary etc)

South

- France

- Italy

- Spain

- Portugal

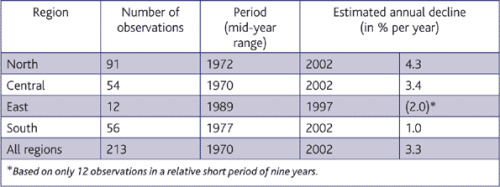

The available observations show a statistically significant decline for the styrene concentrations in the breathing zone of European GRP workers (all regions combined) of 3.3% per year since 1967. We have also estimated the annual decline of the styrene concentration for each region. The results of these estimates are summarised in Table 3. It appears that the annual decline is substantially higher in the north and central regions of Europe in comparison to the south and the eastern part. A graphical presentation of the trend of styrene in the breathing zone of laminators is shown in Figure 4.

The estimated annual decline of mandelic acid concentrations was 7.4% and thus considerably steeper than the average decline of styrene concentrations among European GRP workers as presented in Table 3. It is probable that these urine samples were collected in companies with increasingly lower styrene concentrations in breathing zone air in comparison to the average GRP company in that period.

Study conclusions

About 90% of the retrieved data on styrene exposure (both air, urine and blood samples) is from operators that work in companies where open mould techniques, mainly hand laminating and spray-up techniques are used. Data on styrene exposure during closed mould production of GRP products are rarely available. Data on styrene in blood are scarce in comparison to urinary styrene exposure data, and mandelic acid in post-shift urine is by far the most reported biological marker.

Comparison of the retrieved exposure data concerning the use of polyester resins in the various European countries indicates that a disproportionate amount of styrene exposure measurements were conducted in the Nordic countries compared to the relatively limited styrene exposure data from workers in Spain, Portugal and Eastern Europe.

The exposure data of styrene in the GRP industry retrieved for this review are possibly biased towards higher values, because of non-random sampling. Trend analyses of the available styrene exposure data show that the average styrene concentration in the breathing zone of open mould workers in the European GRP industry has decreased on average 3.3% per year over the period 1967-2002. The annual decline appears stronger in the Northern region (4.3%) than in the southern part of Europe (1.0%). Data on the biological indicators of styrene (mandelic acid in urine) confirm this decline in styrene exposure.

Dr P.M. Bever (PlasticsEurope, Brussels, Belgium), Dr H-P Gelbke (Ludwigshafen, Germany), M. Johansson (Ashland, Brussels, Belgium), Dr Ir. H. Kromhout (IRAS, Utrecht, Netherlands), Dr M. Kogevinas (IMIM, Barcelona, Spain) and Dr G. Triebig (Heidelberg, Germany) are gratefully acknowledged for their assistance, support and advice. This article is based on a study, made on behalf of the PlasticsEurope Styrene Steering Committee entitled Trends and Differences between Regions and Job Categories in Styrene Exposure in the European GRP Industry Period 1970-2002, by J.G.M. van Rooij, Industox Consult, the Netherlands. A scientific article based on this study will be submitted to the Annals of Occupational Hygiene. Industox Industox is professional services consulting firm with extensive expertise in occupational and environmental health. The company and its principal consultants are prominent and respected leaders in the fields of industrial hygiene and occupational toxicology. Quantor Quantor is a consulting company with more than 30 years of experience in the composites industry. The company has an excellent overview of the environmental and occupational aspects of processing thermosetting polymers and advises the industry on regulatory aspects associated with the use of styrene. About the Styrenics Chain at Plastics Europe The Styrenics Chain (SSC) represents European producers and users of styrene. As a cluster of product groups, it operates under the roof of Cefic and PlasticsEurope. The SSC is guided by the principles of responsible care and contributes to a science driven risk assessment of styrene. |