In 2005, the Environmental Protection Agency (EPA) issued the Clean Air Interstate Rule (CAIR) that requires a significant reduction in sulphur dioxide (SO2) emissions across 28 US eastern states by 2015. This has created a great demand for the installation of wet FGD equipment in a number of coal-fired power plants. Wet FGD is the preferred method for SO2 removal from flue gas in coal-fired power plants. It has a global experience base, it is cost effective, and removes up to 99% of the SO2. However, depending on chloride levels and operating pH, wet FGD processes can be highly corrosive to metals.

In the 1990s, high nickel alloy-clad steel was the preferred material of construction for absorber vessels, ductwork and stack liners in wet FGD processes. It had good corrosion resistance and did not cost much more than field-fabricated FRP. Since then, a six-fold increase in nickel price and short supply has made high nickel alloy-clad steel very expensive compared to FRP. Companies such as AEP, Dayton Power & Light, Duke Energy, Santee Cooper, the Southern Company, TVA and WE Energies have chosen FRP for its cost-effectiveness and reliability in wet FGD service. FGD equipment made from FRP is about half the cost of nickel alloy-clad steel, and it has more than 25 years of case histories to back up its use in FGD systems. FRP has been used successfully in stack liners, ductwork, absorber vessels and limestone slurry piping.

Other materials such as rubber-lined carbon steel, acid brick-lined carbon steel and resin-coated carbon steel have been used in wet FGD systems. These materials do not all have the same service life qualities, nor do they have the same cost.

In this article, FRP will be used as a reference material and will be compared to the other materials for service life and cost in wet FGD service.

Cost

With the rising cost of nickel, FRP has become a very competitive material of construction. The total installed cost for FRP ranges from about $125 to $150 per ft2 in North America (prices may vary in other countries). It is very competitive with acid brick or rubber-lined carbon steel (Table 1) and much less expensive than alloy-clad carbon steel. It is generally more expensive than resin-coated carbon steel but has a longer service life in most applications. Because FRP does not require insulation, FRP ductwork is actually less expensive than resin-coated carbon steel (Table 2).

| Construction material | Installed cost ($) | Cost ratio |

| Epoxy vinyl ester resin-coated carbon steel | 1 735 000 | 0.70 |

| FRP made with epoxy vinyl ester resin | 2 475 000 | 1.00 |

| Acid brick or rubber-lined carbon steel | 3 025 000 | 1.22 |

| C-276 clad carbon steel | 4 500 000 | 1.82 |

| Construction material | Installed cost ($) | Cost ratio |

| FRP made with epoxy vinyl ester resin | 1 100 000 | 1.00 |

| Resin-coated carbon steel | 1 265 000 | 1.15 |

| C-276 clad carbon steel | 2 000 000 | 1.80 |

Chemical resistance

Chemical resistance is a key predictor of service life in FGD applications. Compared to metals (Table 3), FRP made from a bis A epoxy vinyl ester resin has as good or better chemical resistance than Alloy C-276 and is superior to 317L stainless steel. FRP has unusual resistance to chlorides and is superior to alloys in high chloride environments. Based on more than 25 years of experience and testing in FGD systems, FRP based on epoxy vinyl ester resin has the chemical resistance necessary for long-term service life.

| Materials | Sulphuric acid | Hydrochloric acid | Acid chloride salts |

| 317L stainless steel | 25°C below 5% | NR | NR |

| FRP made with bis A epoxy vinyl ester resin | 100°C to 30% | 80°C to 15% | 100°C all conc. |

| Alloy C-276 | 100°C to 30% | 80°C to 15% | 65°C to 20M ppm at low pH |

FRP

The use of FRP in coal-fired power plant FGD systems dates back to the 1970s. FRP has been used extensively in limestone slurry piping systems and to a lesser degree in stack liners. In the 1990s several large scrubbing vessels were made from FRP. The power industry was slow to accept the use of FRP in large scrubber vessels due to concerns for high upset temperatures. Improvements in FRP technology have eased temperature concerns by demonstrating the ability of epoxy vinyl ester resin based FRP to withstand upset temperatures of 315°C (600°F).

Because not all resins are suitable for processes that have thermal cycling or high temperature excursions, it is important to consult the resin manufacturer when choosing a resin for these types of applications.

Case histories

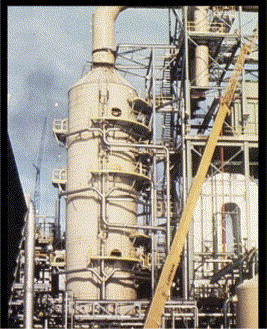

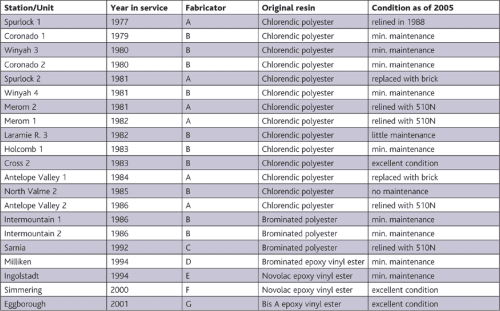

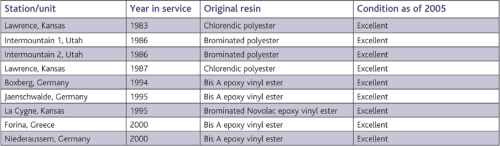

FRP case histories include absorber towers, slurry piping, ductwork and stack liners. The use of FRP in stack liners and slurry piping began in the 1970s. Several ducts were installed in the 1980s, and a few large absorber towers were built in the 1990s. The most common material of construction for slurry piping (Figure 2) in wet FGD systems is FRP based on epoxy vinyl ester resin. With an abrasion-resistant liner, FRP pipe based on epoxy vinyl ester resin has been successful in more than 150 plant sites dating back to 1977. Brominated epoxy vinyl ester resins are used on projects that require fire protection. The second largest use of FRP in wet FGD is stack liners. Since 1977, a number of FRP stack liners have been installed and are still in service today as shown in Table 4. Two were removed due to faulty construction and replaced with acid brick linings. Fabrication errors were the root cause for having to reline five liners. These have been very successfully relined with brominated novolac epoxy vinyl resin. The rest are in good to excellent condition and require minimum maintenance. One factor that inhibited the use of FRP in absorbers and stack liners in the power industry was the 1980s experience with stack liners. Although many were successful, a few notable exceptions caused concern about FRP in the minds of many engineers and owners in the 1980s. Since that time it has become obvious that fabrication errors were the root cause. By the early 1990s standards such as ASTM D5364 and ASME RTP-1 for material selection, design, fabrication, erection and quality control were developed to help avoid fabrication errors. Owners became more aware of the importance of inspection and workmanship and were willing to take ownership of these important factors to avoid the mistakes of the past. These important developments led to the successful construction and operation of stack liners, ductwork and absorber vessels in the 1990s. FRP stacks and stack liners made from epoxy vinyl ester resin are shown in Figure 3, Figure 4 and Figure 5. These are located in New York, Germany and Austria respectively and have been in service with start-up dates ranging from 1994 to 2000.

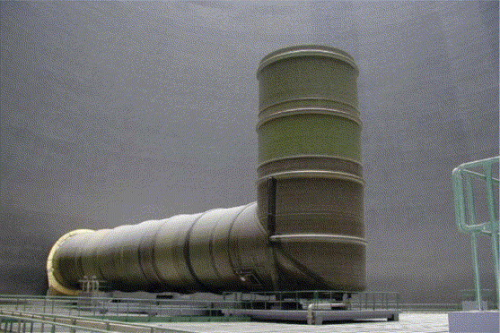

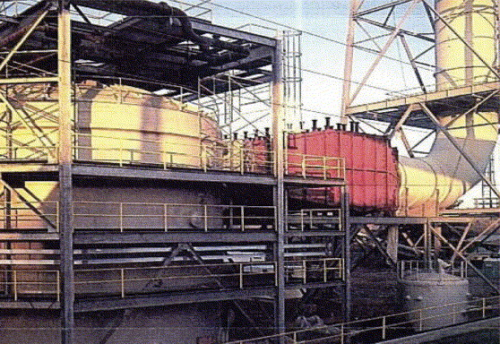

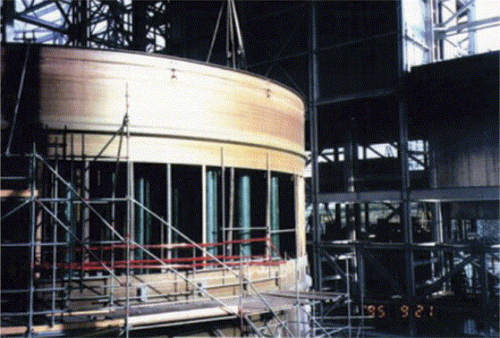

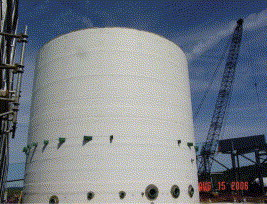

Some of the first large FRP absorber vessels for FGD are shown in Figure 8 and Figure 9. The vessel in Figure 8 was made from brominated epoxy vinyl ester resin. The vessel, known as a jet bubbling reactor (JBR), the ductwork and stack were fabricated on site in Yates, Georgia, USA. The JBR is part of a limestone slurry FGD process that has all the chemical reactions taking place in one vessel to produce high quality gypsum. The most massive operational FRP absorber vessel in the world (Figure 10) was fabricated on site in Alberta, Canada, in 1996. This vessel was also a JBR and was made with DERAKANE 411-350 epoxy vinyl ester resin. The FRP shell alone weighed 89.4 tonnes (197 000 lbs). It is 20.7 m (68 ft) in diameter and 19.8 m (65 ft) tall. Some of the largest FRP absorbers in Europe (Figure 11) were made from DERAKANE epoxy vinyl ester resin. They are both 9 m (29.5 ft) in diameter and 49 m (160.8 ft) tall and have been in service since 1998.

New construction

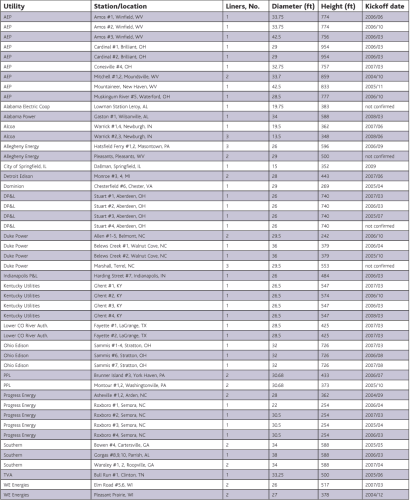

Since the EPA issued the CAIR in 2005, there has been an unprecedented demand for FRP as a material of construction in wet FGD applications. Table 6 is a summary of 49 locations in the USA that are using FRP for stack liner construction. With over 3 million ft2 of laminate, this is the largest use of FRP for stack liners in the history of the power industry.

Proven performance

FRP made with DERAKANE™ or HETRON® epoxy vinyl ester resin is an ideal material of construction for FGD stack liners, ductwork, absorber towers, limestone slurry piping and spray headers with the following advantages:

- proven performance over 30 years;

- much lower cost than Alloy C-276 clad carbon steel; and

- less maintenance than other materials.