The global wind industry is growing fast, in terms of both the number of turbines and their sizes. According to the Global Wind Energy Council (GWEC), modern turbines are 100 times the size of those in 1980. Over the same period, rotor diameters have increased eight-fold, with turbine blades surpassing 60 m in length. By the end of 2007 around 20 GW of capacity had been installed, bringing the world total to almost 94 GW. In its report Global Wind Energy Outlook 2008, GWEC predicts that wind will supply 12% of the world’s energy needs within the next 12 years, and could supply 30% by 2050.

Wind turbine blades typically consist of reinforcement fibres, such as glass fibres or carbon fibres; a plastic polymer, such as polyester or epoxy; sandwich core materials such as polyvinyl chloride (PVC), PET or balsa wood; and bonded joints, coating (polyurethane), and lightning conductors.

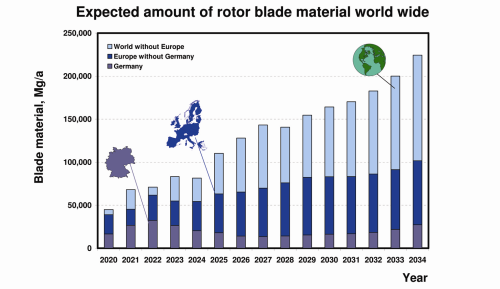

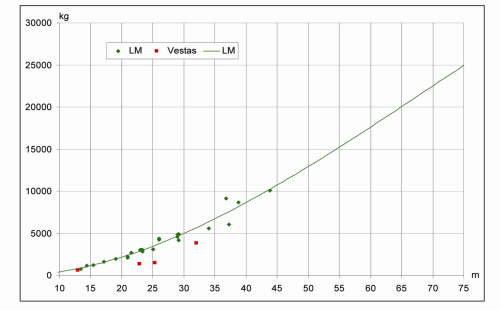

As the turbines grow in size, so does the amount of material needed for the blades. Professor Henning Albers from the Institut für Umwelt und Biotechnik, Hochschule Bremen, estimates that for each 1 kilowatt (kW) installed, 10 kg of rotor blade material is needed. For a 7.5 megawatt (MW) turbine, that would translate into 75 tonnes of blade material. In a presentation at Composites Europe in September 2008, Albers predicted that by 2034, around 225 000 tonnes of rotor blade material are up to be recycled per year worldwide. [See diagram on the right.]

Wind turbine blades are predicted to have a lifecycle of around 20-25 years. The question is what to do with them afterwards.

In the paper Managing Long-term Environmental Aspects of Wind Turbines: a Prospective Case Study in the International Journal of Technology, Policy and Management, Vol. 7, No. 4, 2007, Per Dannemand Andersen, Mads Borup and Thomas Krogh at the Technical University of Denmark make the prediction that from 2040, 380 000 tonnes of fibre composites will have to be disposed of each year:

“Because the wind-turbine industry is relatively young, there is only a limited amount of practical experience on the removal … of wind turbines, particularly in respect of offshore wind turbines. It is likely to take more than 20 years before a substantial amount of practical experience regarding the dismantling, separation, recycling, disposal, etc., of wind-power systems is gained.”

At the moment, there are three possible routes for dismantled wind turbine blades: landfill, incineration or recycling. The first option is largely on its way out with countries seeking to reduce landfill mass. Germany, for example, introduced a landfill disposal ban on glass fibre reinforced plastics (GRP) in June 2005, due to their high (30%) organics content such as resin and wood.

The most common route is incineration. In so-called combined heat and power (CHP) plants, the heat from incineration is used to create electricity, as well as to feed a district heating system. However, 60% of the scrap is left behind as ash after incineration. Due to the presence of inorganic loads in composites, this ash may be pollutant, and is, depending on the type and post-treatment options, either dumped at a landfill or recycled as a substitute construction material. The inorganic loads also lead to the emission of hazardous flue gasses in that the small glass fibre spares may cause problems to the flue gas cleaning steps, mainly at the dust filter devices.

Wind turbine blades also have to be dismantled and crushed before transportation to incineration plants, placing further strain on the environment in terms of energy used and emissions. Henning Albers suggests that there are also cause for concern in relation to the health and safety of workers involved in the incineration process.

The alternative is recycling – either material recycling, or product recycling in the form of re-powering where old turbines are replaced by newer, more efficient ones. At the moment, however, there are few established methods for the recycling of wind turbine blades, and only 30% of fibre reinforced plastic (FRP) waste can be re-used to form new FRP, with most going to the cement industry as filler material.

REACT

Between 2003 and 2005, a project led by the consultancy company KEMA and the Polish Industrial Chemistry Research Institute (ICRI) looked at the mechanical recycling of FRP, including wind turbine blades, where the material is ground and then re-used. Funded by the European Commission CRAFT project, the REACT project also involved HEBO Engineering, C-it, Fiberforce Composites Ltd, Hamos GmbH, Plasticon, ZPT and the European Composite Recycling Services Company (ECRC).

The REACT consortium, through HEBO and KEMA, designed, built and tested a hybrid shredder for ‘fit-for-purpose-size’ reduction. The shredder has a capacity of 2.5 tonnes/hour and can reduce FRP to 15-25 mm with “minimal internal damage” to the fibres. This was done with hammers slamming the resin out of the fibre structure. To avoid dangerous situations during grinding, an electronic sensor for volatile organic compounds (VOC) was developed by C-it.

After shredding, the fibre was upgraded by a reactivation method, specially developed by ICRI to achieve better properties through a new chemical bonding with the new matrix. Another technology was developed by HAMOS for fibre length separation, and the removal of undesired impurities.

One of the problems in reusing shredded FRP waste is to rebind fibres with the new resin, as the shredded fibres often have resin residues, making bonding more difficult. Talking to Reinforced Plastics, Bart in’t Groen, consultant at KEMA, remarks: “you need longer fibres to have good bonding with your new matrix compared with virgin fibres.”

For wind turbine blades, an additional step is required. The blades must be cut into chunks on location to ease transport. This can be done with a demolition claw (a crushing/grabbing claw attached to the end of a crane or digger), a technology which is widely available.

Initially, the REACT project aimed high when it came to possible applications for FRP recyclate, but found that there was not the same demand for composite recyclate as for materials such as steel. The consortium therefore started looking at smaller, more niche markets. Examples include parts for FRP silo tanks, reinforcement of concrete, new hand laminate products, reinforcement of recycled polyproplene (PP) resin, sand-resin mixture for producing large flower pots, and sandwich panels.

One challenge that arose when turning to the composite industry itself was product guarantee certificates, as found in the boat building industry. When using recyclate, companies often feel they are taking a risk with the materials, thereby endangering their guarantee certificates.

Another challenge is that recycled fibres will be shorter than original fibres, coated with some ‘historical’ resin, and are harder to arrange in a given direction. This makes it more difficult to increase strength, as is needed, for example, in car bumpers. This has not stopped the car industry from recycling and reusing its own waste, however. According to in’t Groen, it is just a matter of knowing your input material.

Despite these challenges, he is keen to point out that the recycling of FRP materials, including wind turbine blades, is important: “Because composite usage and so its end-of-life waste will increase enormously, so a lot of initiatives are there and solutions will be found. It’s a waste dumping this material.”

However, Dr Richard Court, Technology Specialist – Wind Renewables at the New and Renewable Energy Centre (NaREC), points out that “grinding uses a lot of energy due to the hardness of the glass, and the value of the filler is quite low, so it is not easy to make it economic – unless you find a cheap source of energy.”

ReFiber

Erik Grove-Nielsen, of ReFiber ApS in Denmark, remarked in a presentation at Borås University in Sweden in 2007 that mechanical recycling in the form of material crushing retains the tensile strength of glass fibre, but that it gives impure end-materials. The filler market is flooded with similar materials such as chalk, and the energy content is not recovered.

A recycling possibility is chemical recovery through solvolysis. With this method, most of the tensile strength of the glass fibre is retained, and the plastic material can partly be used as new raw material. However, Grove-Nielsen questions the use of aggressive and hazardous chemicals, and highlights the high cost.

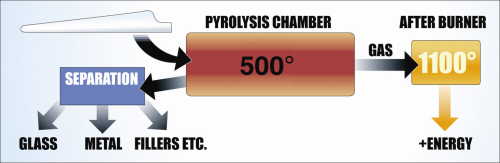

| ReFiber’s recycling concept in short is as follows: |

|

The option favoured by ReFiber is thermal and material recovery in the form of pyrolysis and gasification. Although the fibres lose a “considerable part” of their original tensile strength, and despite the high cost of the technical plant, the end product is very “homogenous,” and the energy content of the plastic is recovered in the form of electricity and heat.

The end products from ReFiber’s pyrolysis are primarily thermo-resistant insulation materials. The fibres can also be used for fibre-reinforcement in filler, glue and paintings, thermoplastic parts, asphalt and concrete; and raw material for new glass fibres. The energy content of the composites is used for generating electricity, for process energy and district heating.

Grove-Nielsen does not believe that the recycled GRP wind turbine blade material can be reused in new blades, however: “Recycled glass fibres will always have lower strength than virgin materials. Therefore the industry cannot use recycled reinforcement fibres. For carbon fibres it is different. ReFiber has recovered, in its pyrolysis facility, carbon fibres from prepreg epoxy/carbon material with unchanged E-modulus and only 5% lower values for ultimate tensile strength. Still, for the glass fibre, it makes sense to allow the glass fibres to ‘retire’ for a life as a heat insulation material in buildings.”

Despite ReFiber’s apparent success in establishing a disposal and recycling route for GRP and wind turbine blades, finances have stopped the project:

“As of today, most Danish worn-out blades and production failures are sent to landfill, as this is the cheapest solution for the companies,” says Grove-Nielsen. “ReFiber tried to get finance for a 5000 tonnes/year recycling facility, [but] as it is possible to dump the material on landfills, [that] is what is done. The possible investors didn’t feel safe … so we had to set the project on stand-by for some time.”

| It makes sense to develop a recycling industry to maturity before the big amounts arrive. |

| Erik Grove-Nielsen, ReFiber ApS |

The 5000 tonnes/year facility would be fed by approximately 4000 tonnes of production waste from the Danish GRP industry, 500 tonnes/year from worn-out wind turbine blades, and 500 tonnes/year of other glass fibre waste. Grove-Nielsen predicts that there may be a supply of blades from the wind turbine retrofit market in Northern Germany in the near future, as older, smaller turbines are decommissioned and replaced by new, bigger and more efficient versions. There is also the possibility that some of the better turbines may be sold to Eastern European countries for a ‘second life.’

“For the early years we will have to depend on delivery of production waste and worn out GRP products other than blades. The real big amounts of worn out blades will emerge 15 years from now. It makes sense to develop a recycling industry to maturity before the big amounts arrive,” Grove-Nielsen comments.

In 1995, the Danish government passed legislation banning the disposal of rubber car tyres on landfill and through incineration, which created a new recycling industry for car tyre rubber, but no such approach has been taken for GRP.

“We asked the government here to do the same for GRP recycling, but they want ‘the market’ to solve the problem,” Grove-Nielsen says.

Viability

Talking to Reinforced Plastics, Per Dannemand Andersen, Head of Section, Department of Management Engineering, Technical University of Denmark, suggests that the problem is not the material itself, but the lack of volume, making recycling financially difficult: “There are now technologies available to reuse fibre-glass and blades from wind turbines and other components in cars. The problem is not technologies, but … that there is not enough scrap … so it is not commercially viable to put up a plant that could use only these blades.”

| Recycling is going to become more important ... for environmental reasons, but also for economic reasons. |

| Thomas Wegman, Reichhold and ECRC |

A similar point was made by Thomas Wegman, Director Global Account Management at Reichhold Composites and Chair of the European Composite Recycling Company (ECRC). ECRC has an active conversion system in place in France, where composite materials are reduced to smaller parts, fibres and powders, and then sold on to different applications. To their surprise, the amount of material offered for recycling and processing does not amount to what the outlets are capable of receiving.

“I think the reality is that the quantity of waste that is offered to us, as well as other companies, is relatively small. If you’re talking about waste streams that can be used in cement manufacturing, people are looking at hundreds of tonnes per week – well, I think we’re currently receiving tens of tonnes per year,” Wegman says.

Court at NaREC, however, believes the material is part of the problem: “Industries that use a lot of thermoset composite materials tend to make longer-lived items, and are probably waiting to see what, if any, recycling options are developed in the coming years. I am sure the wind turbine blade industry would welcome any research into recycling of thermoset composites – although from my own awareness of the materials and chemistry of thermosets, it’s difficult to see what those recycling options could possibly be. Recycling thermoset composites is certainly a major challenge, and it will be interesting to see what developments are forthcoming.”

Wegman at Reichhold and ECRC is more optimistic looking 15-20 years ahead in time: “I would say that recycling is going to become more important … for environmental reasons, but also for economic reasons.”

Who’s responsibility?

Who is responsible for what happens to wind turbine blades at the end of their life cycles? Albers says that typically the responsibility ends up with the manufacturer of the end product, as seen in the car industry.

As far as Reinforced Plastics has been able to establish, there is no European-wide legislation in place for the recycling of wind turbine blades. Wegman believes this could come at some point in the future, whilst remarking that “there is a desire from the manufacturing companies and the people involved in composite businesses to find ways to actively [find solutions] and not wait for legislation to come.”

Working with the ECRC, Wegman finds that the waste streams are not unmanageable at the moment, but a solution must be found. “We will work step by step towards a sustainable structure based on commercial outlets for composite waste. ECRC has access to unlimited industry expertise to make this happen.”

New materials

| Composite recycling companies |

|

Some thought has gone into developing new ways of producing wind turbine blades to make the disposal and recycling process easier. Court at NaREC explains: “There are … thoughts about trying to use thermoplastic matrix composites in wind turbine blades, the idea being that thermoplastics are easier to recycle, as evidenced in the automotive sector. Whether the mechanical and physical performance of the thermoplastic based materials is sufficient for a multi-megawatt wind turbine blade has yet to be proven. For micro-wind turbines, e.g. up to around 5 kW, it is possible to, and some do, use some form of moulded thermoplastic, reinforced or otherwise – in which case recycling is much more of a possibility.”

In September 2008, Risoe DTU announced it is aiding the Chinese forestry commission to examine the use of bamboo in wind turbine blades. The blades will initially be made from bamboo shreds glued together using epoxy, but the hope is to be able to replace the synthetic epoxy material with a bio-based adhesive.

Reichhold and ECRC’s Wegman believes it is not just about making the resins more recyclable or greener: “When you make a complex product like windmill blades, it’s not just one material, it’s … a system. Sometimes there are metal parts inside for specific functional reasons and there are different core materials which can range from PVC to balsa wood – so it’s a complex system.

“For Reichhold as a company to just develop a specific resin that would be more easily recycled – I don’t think that’s what we’ve looked at, as this is only one element of a composite system – we’ve taken the route of working together with some other companies making reinforcements, fillers and other components to take an integrated approach and to get rid of the waste and reusing the waste in a good way.”

Philipp Angst, Product Manager Core Materials at Alcan Airex, part of Alcan Composites Core Materials based in Switzerland, advocates the use of polyethylene terephthalate (PET) foam in wind turbine blades:

“PET foam is [being] adopted by more and more wind companies. It is a thermoplastic structural foam that is fully recyclable. You can recycle it and put it back into production. It is clearly the concept for the future in wind blade production. It must be ground/shredded and then mixed back into new products. It keeps the same properties and strength.”

Alcan Airex already recycles its own PET foam, AIREX® T91.

It appears from the above that the recycling of wind turbine blades is still seen as somewhat problematic, but that progress has been made in both methods for recycling GRP and possible applications for the recyclate. With the amount and size of wind turbines ever increasing, it is clear that there will be significant waste to handle in 15-20 years, but also that the industry is waking up to the challenge – not only in terms of recycling, but also in research into new materials. And if there is one thing that all our experts agree on, it is that the recycling is the way forward for making wind energy even greener.