Part 2 of this article describes how Umicore has developed an alternative to traditional cobalt accelerators. Part 1 looks at the reasons why an alternative is needed.

ECOS ND 15

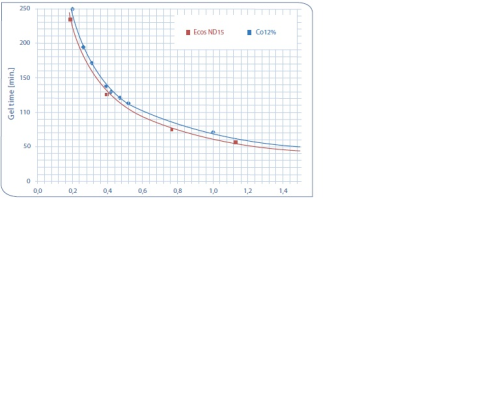

In order to address the environmental and health risks related to the use of traditional cobalt accelerators Umicore has developed an alternative, ECOS ND®15. The Bruges factory of Umicore in Belgium produces both polymer- and metal-based chemicals. As a result, the development combines both technologies to make a new, cobalt containing polymer. Cobalt is built within the structure of the polymer and is not released as an ion. Since polymers cannot be absorbed by living bodies as easily as monomers, the toxicity of this substance was expected to be much lower. This has now proved to be the case. Tests with ECOS ND®15 for the curing of unsaturated polyester resins have shown that the performance is very similar to the performance of a traditional cobalt-based accelerator. The same goes for gelcoats, where ECOS ND®15 is successfully used as well. An example is given in Figure 3, where the gel time is plotted as a function of the amount of accelerator used in a standard medium-reactive ortho phthalic polyester resin for vacuum infusion. Generally, non-cobalt metal complexes do not follow the same behaviour as cobalt bis(2-ethylhexanoate), thus the formulation has to be significantly modified to obtain the same gel time and peak exotherm. In contrast, ECOS ND®15 showed close to a 1:1 replacement for the whole range of typical UPR cobalt concentrations. As already mentioned ECOS ND®15 is a polymer. Therefore it is not subject to the REACh legislation. Nonetheless, in order to comply with actual and anticipated legislation, Umicore has undertaken to document a full toxicity file on its new technology. Tests have been performed in correspondence to Annexes VII and VIII of the REACh regulation (EC/1907/2006). All mechanistic toxicology assessments were performed in collaboration with the Fraunhofer Institute for Experimental Medicine (Fraunhofer ITEM, Hannover, Germany). The cobalt polymer consists of a high-molecular-weight matrix in which cobalt is incorporated. Its reduced solubility in aqueous media will also limit its bio-accessibility. It shows that its bio-accessibility in body fluids (lung fluid and intracellular fluid) was assessed to be more than 100 times lower than that of cobalt sulphate. Its solubility in distilled water proves to be more than 10,000 times lower than that of cobalt sulphate. The bio-availability is a significant parameter within the entire toxicological profile. Reactive Oxygen Species (ROS) formation was studied because of the potential of cobalt ions to generate ROS and the potential of ROS to cause genotoxicity. It was demonstrated that the cobalt polymer does not induce any ROS formation at biologically relevant concentration levels. In a subsequent part, the modified Comet Assay was performed. In addition to detection of DNA cleavage events (DNA damage), this technique allows monitoring of ROS-driven DNA modifications. The presence of genotoxicity is considered a required precedent of primary carcinogenicity. The cobalt polymer did not demonstrate any DNA damage (DNA strand breaks or oxidative modifications) at biologically significant concentration levels. Further eco toxicological endpoints, toxicological endpoints and physicochemical characteristics have been evaluated. Again all results confirm the non-hazardous character of the cobalt polymer. The outcome is communicated via a Material Safety Data Sheet. The most relevant endpoints include:

- The cobalt polymer is not classified for acute nor chronic aquatic toxicity, while cobalt bis(2-ethylhexanoate) is classified as aquatic acute toxic category 1 and aquatic chronic toxic category 3.

- The cobalt polymer is not skin sensitising, while cobalt bis(2-ethylhexanoate) is skin sensitising category 1A.

Conclusions

ECOS ND®15 is a cobalt-based technology. Performance and toxicological aspects have been addressed in all details. The cobalt polymer proves to be a non-hazardous substance and is a drop-in replacement and a 1:1 substitute which makes it very easy to introduce in existing formulations. This new cobalt technology is the sustainable solution for accelerators in structural unsaturated polyester resins and gelcoats.

This article will be published in the May/June 2014 issue of Reinforced Plastics magazine.

The digital edition of Reinforced Plastics is distributed free of charge to readers who meet our qualifying criteria. You can apply to receive your free copy by completing this short registration form.