Polyester is one of the major composite materials used in automotive, marine and construction applications. It combines several advantages such as a light weight, relatively low cost and good structural properties. The consumption of unsaturated polyester resins (UPR) in Europe is estimated in 500.000 tons annually. European polyester manufacturers are living in uncertain times. Not only has demand suffered due to the recent economic downturn, uncertainty about upcoming changes in chemical regulations leave them with doubts on the raw materials that they will be allowed to use in the future. At the centre of this discussion is the use of cobalt accelerators. Cobalt carboxylates, mostly cobalt bis(2-ethylhexanoate) - also known as cobalt octoate - are widely used as accelerators for unsaturated polyester resins. The total annual consumption in Europe for cobalt based accelerators in the composite industry can be estimated at around fifty tons of metal. Accelerators typically contain between 1-12% of cobalt metal.

Cobalt

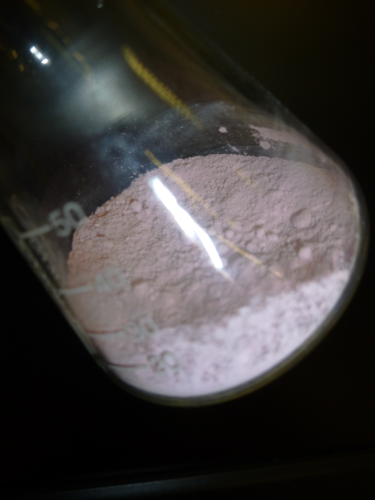

Cobalt is a transition metal with the atomic number 27. On the Periodic Table of Elements it is found between iron and nickel. Cobalt has been used since ancient times as a colourant in ceramics. Usually it is found in nature in low concentrations; it is an essential element for the human body, since it is the nucleus of vitamin B12, a complex organic molecule around a cobalt atom. Vitamin B12 is necessary for the synthesis of DNA. Nowadays cobalt is mined all over the world, from Turkey to Australia, and from Russia to Zambia. The most important industrial application of the cobalt is the manufacturing of rechargeable batteries. These typically contain a mixture of lithium, cobalt and nickel. Other applications of cobalt include driers in inks and coatings, components of superalloys and hardmetals, and rubber adhesion promoter in tyres. The atom valence of cobalt changes easily between +2 and +3; therefore it facilitates the transfer of electrons and the formation of reactive free radicals. This results in cobalt being an excellent oxidation catalyst in many kinds of chemical processes. One example of cobalt as an oxidation catalyst is its use in unsaturated polyester resins; cobalt is by far the most used catalyst (or ‘accelerator’, as it is called in the polyester industry). The cobalt-ion remains unchanged after the reaction, but it is very effective in activating peroxides and organic molecules to react with each other. These reactions lead to crosslinking between the resin molecules, and determine the final mechanical properties of the polyester. Therefore the catalyst efficiency is of vital importance for the quality of the end product.

REACh

In the European Union, the regulation for the use of chemical substances has been centred around REACh since 2007. The toxicological assessment of chemical substances is to be carried out by the industry itself. In 2010, a first group of organic cobalt salts was registered. Among these substances is cobalt bis(2-ethylhexanoate). In June 2013 other cobalt carboxylates, among them cobalt neodecanoate, were registered as well. The toxicity of cobalt carboxylates is not yet fully known. A test programme is on its way as part of the REACh registration follow-up, which may result in more stringent hazard classifications in particular with regard to the CMR endpoints (carcinogenicity, mutagenicity and reproductive toxicity). Five inorganic cobalt salts (including cobalt chloride, cobalt sulphate, cobalt acetate, cobalt nitrate and cobalt carbonate) are already classified as carcinogenic by inhalation category 1B. Since cobalt 2-ethylhexanoate shows various similarities to cobalt chloride, the potential carcinogenic aspect of cobalt carboxylates is a serious subject of anxiety. Such hazard classifications result in restrictions in use and concentration limits in mixtures which may not be surpassed without the mixture being classified as CMR. As an example, for cobalt compounds that are classified as lung carcinogens category 1B, the concentration of cobalt that should not be exceeded in mixtures may become as low as 0.01% cobalt (expressed as cobalt metal content). It is clear that this would jeopardise the use of cobalt carboxylates in inks, coatings and UPR, since the active cobalt concentration required is normally higher than 0.01%.

This article will be published in the May/June 2014 issue of Reinforced Plastics magazine.

The digital edition of Reinforced Plastics is distributed free of charge to readers who meet our qualifying criteria. You can apply to receive your free copy by completing this short registration form.