"After a very mixed year last year, we are very optimistic about 2013," affirms Arnaud Genis.

"Our view is that the worst of the European crisis is over, that the emerging economies which did not perform as expected last year – mainly India and Latin America – are recovering, and the US is entering into a strong phase of growth."

Recovery in the US market

Owens Corning believes that the US is poised for a strong and sustainable growth, in line with predictions outlined by market research firm Lucintel during a COMPOSITES 2013 conference presentation (see US composites market on the up).

There are three main markets in US fuelling this growth, says Genis, and at number one is construction.

"Obviously construction is important to Owens Corning as we are half a building materials company and half a composites company, and within composites we have a lot of applications in the US related to construction," he explains. "There is the big roofing and shingle market, but more broadly in construction, window profiles, shower/tub, doors etc. On average a US house consumes 100 kg of glass. Housing starts are growing from 750,000 this year to 1 million next year, so that’s huge growth."

The second market is global and related to energy – the extraction of shale gas.

"This is driving a lot of composites useage, not only related to fracking but also water storage," Genis told Reinforced Plastics. "This has driven a lot of growth for us last year, mainly because of the need for anti-corrosion glass and we are uniquely positioned here with our Advantex technology."

The third US growth market is automotive.

"We see very good momentum and renewed innovation in the automotive field," notes Genis. "And with the CAFÉ [Corporate Average Fuel Economy] regulations, and in parallel to that the European regulations on CO2 emissions, people are now actively working on finding solutions to take weight out of vehicles. With all the technology platforms we have we are very well positioned to develop materials for structural and semi-structural automotive applications."

Owens Corning is partnering with several companies in the automotive industry to design these new materials. Although these companies cannot be named because of confidentiality agreements, Genis emphasises that Owens Corning is dedicating a lot of R&D resources to this area. In March, the company announced it was joining BASF and TenCate Advanced Composites in a strategic alliance focused on the development of thermoplastic automotive composites. (See Owens Corning joins TenCate/BASF alliance for thermoplastic automotive composites.)

'Best in class' strategy

Owens Corning has now emerged from a period of time during which it was focussed on optimising its manufacturing assets. The acquisition of Vetrotex in November 2007 was followed by a major integration project aimed at bringing together the best of both companies.

"We had to take structural actions to bring our costs in line with what they needed to be," Genis explains. "We shut down several high-cost lines in Asia and in Europe, and we built a new low-delivered-cost network with the start up of new furnaces in Russia and Mexico, and a new plant in China."

The company believes it now has the ideal cost base, and its focus going forward is on developing 'best in class' products.

"Last year we launched four new products on the market," Genis reports. "This year we will launch eight. And when we talk about best in class products it’s not ‘me too’ products, it’s those which are benchmark. Benchmark for me is when you’re similar to others and best in class is when you really work on the cost/performance curve to define where you want to position yourself. And then you put your scientists to work on this so that when you go to the market you can allow your customers to redesign their products."

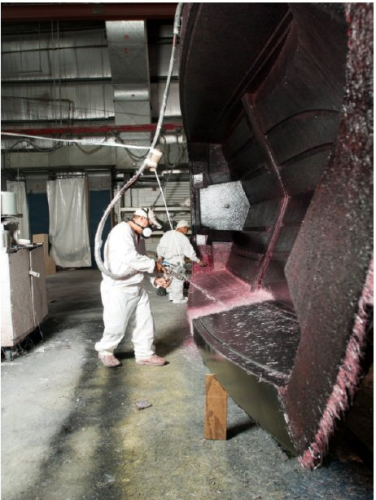

He points to the OptiSpray™ family of multi-end rovings made with Owens Corning's Advantex® E-CR glass fibre as an example of this. OptiSpray is said to offer improved surface quality and excellent mechanical properties in the final part, while offering cost savings resulting from improved efficiency, less downtime, and potentially lower resin consumption (see box below for further information).

Capacity utilisation drives pricing

On the question of glass fibre pricing, Genis talks about two drivers. The first of these is capacity utilisation.

"Pricing in this industry is very much related to capacity utilisation and our market intelligence tells us that by the middle of this year capacity utilisation will be at a high level, and next year it will be in the territory where availability starts to become a concern," he notes.

He also points out that it is becoming very difficult for Chinese glass fibre producers to add capacity as the Chinese government has reduced its support for capacity expansion to focus on forward integration and cost reduction. Owens Corning believes the Chinese composites market is going to grow by more than 10% this year and this means several furnaces in China will have to be redirected from export to domestic production. This will drive prices up.

|

In September 2012, Owens Corning announced the global availability of its OptiSpray multi-end rovings, which are designed to provide optimal performance in spray-up processes. The products can be used in the production of swimming pools, boat hulls, transportation parts and other items. OptiSpray is made with Owens Corning’s patented Advantex glass fibre which combines the electrical and mechanical properties of traditional E-glass with the corrosion resistance of EC-R glass. OptiSpray Roving grade is designed to provide optimal performance for spray-up applications where standard wet out speed is preferred in complex moulds. OptiSpray H offers the added benefit of good lay down in large, flat moulds with a consistent surface finish. The OptiSpray F version is designed for applications that require faster wet out in complex moulds or sharp curvatures, either due to the resin system or in high throughput operations. OptiSpray is said to provide optimum wetting for good surface finish and mechanical strength in the finished product. Processing benefits include: easy chopping, rolling and air release; flat lay down and uniform dispersion; excellent conformability without spring back; optimal resin consumption; and excellent performance in vertical parts. Owens Corning claims OptiSpray products can improve manufacturing efficiency with less down time and potentially lower resin consumption. When selecting the glass roving suitable for a particular application, wet-out characteristics are critical. Regal Boats, an Orlando, Florida-based manufacturer of boats in the 19-52 ft range, has trialled OptiSpray F gun roving in its production process. “The first thing we noticed was the speed of the glass wet out,” reports Pat Wiesner,” Regal Boats VP of Engineering. “We were able to reduce the resin by 3% to 5% compared to the gun roving we used previously. This reduction in resin saves us both money and weight, and both are important considerations when building boats.” |

In addition, the European market in the 2012 fourth quarter was a little soft and the high cost producers in Europe were wondering if they could manage to load their assets, Genis reports. Doubts on the PTC [production tax credit for wind power] extension in the US also triggered some concerns. However he believes all the indicators are now green and that by the summer of this year capacity utilisation is going to drive prices up.

The second driver of price is value creation.

"When we work on our best in class agenda obviously we look at sharing the value we create with our customers," Genis notes. "We want our customers to be more profitable but not at our expense."

Genis believes that the pricing environment has been very challenging and that achieving improved profitability will be necessary in order to justify reinvestment.

"We have invested a lot in restructuring our network, in building these low delivered cost platforms. We feel that we have the right fleet of furnaces, we have the right capacities, now it’s a matter of loading them with the right products, the right customers and the right projects."

He is also optimistic about forecast market growth, which will enable the industry to focus on the future and regain the momentum of the penetration of composites against other materials. ♦

This article will be published in the May/June 2013 issue of Reinforced Plastics magazine.

The digital edition of Reinforced Plastics magazine is distributed free of charge to readers who meet our qualifying criteria. You can apply to receive your free copy by completing the registration form.