Metrology company Hexagon Manufacturing Intelligence has launched a composite inspection system which it says can inspect and analyse lightweight carbon-fibre components more quickly.

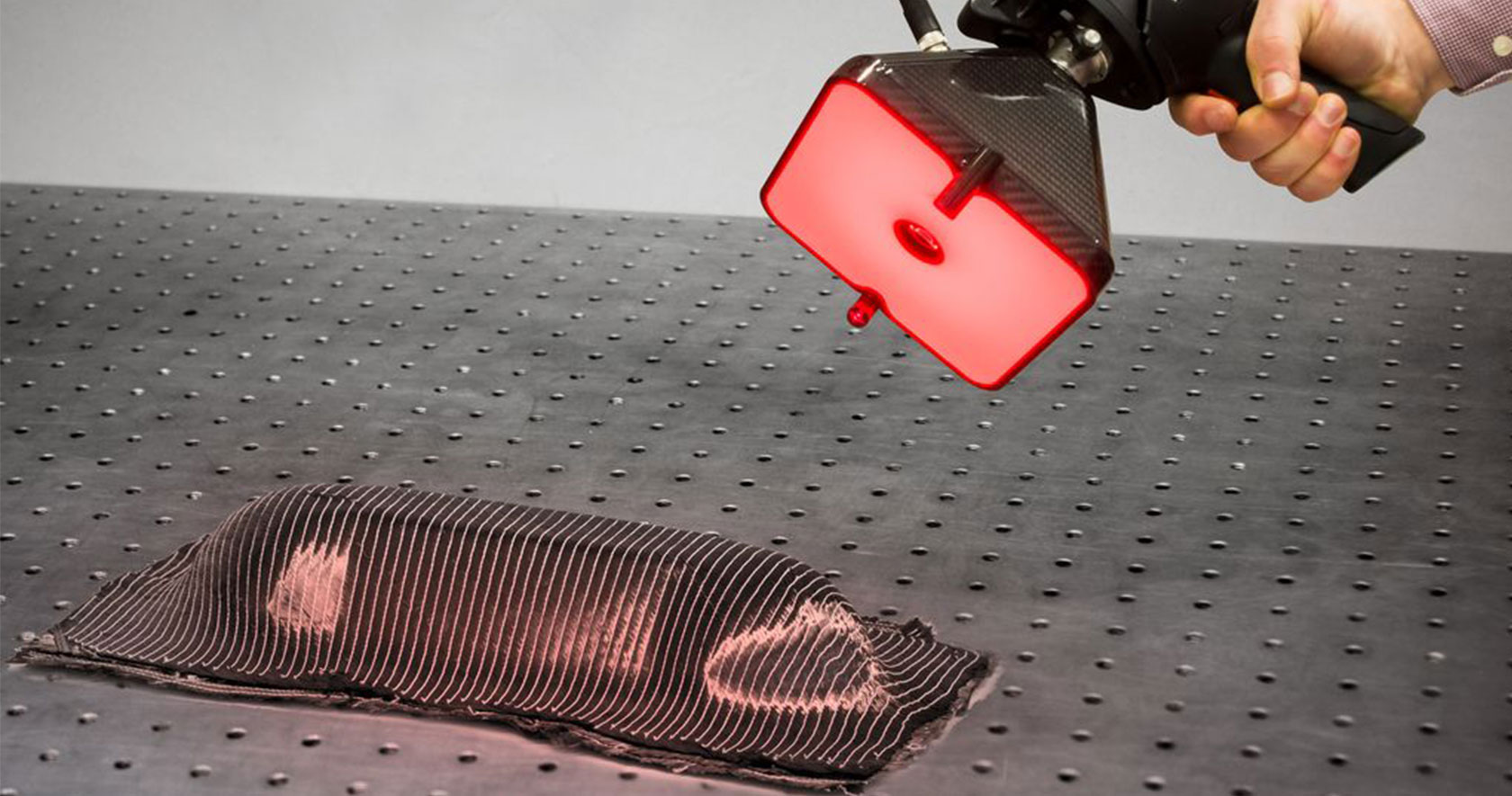

The system includes HP-C-V3D Apodius Vision Sensor camera-based scanning hardware designed to fit to a ROMER Absolute Arm with Integrated Scanner and the Apodius Explorer 3D software package. The system can carry out fiber orientation, geometry measurement and three-dimensional model creation and analysis, the company says.

‘Until now, three-dimensional digitisation has required the sensor to be robot-mounted,’ said Alexander Leutner, managing director of Apodius, which makes composite inspection systems. With the technology of the ROMER Absolute Arm we’ve been able to deliver portable hand-guided composite inspection for the first time, resulting in a much faster and more convenient digitisation process.’

This story uses material from Hexagon MI,with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.