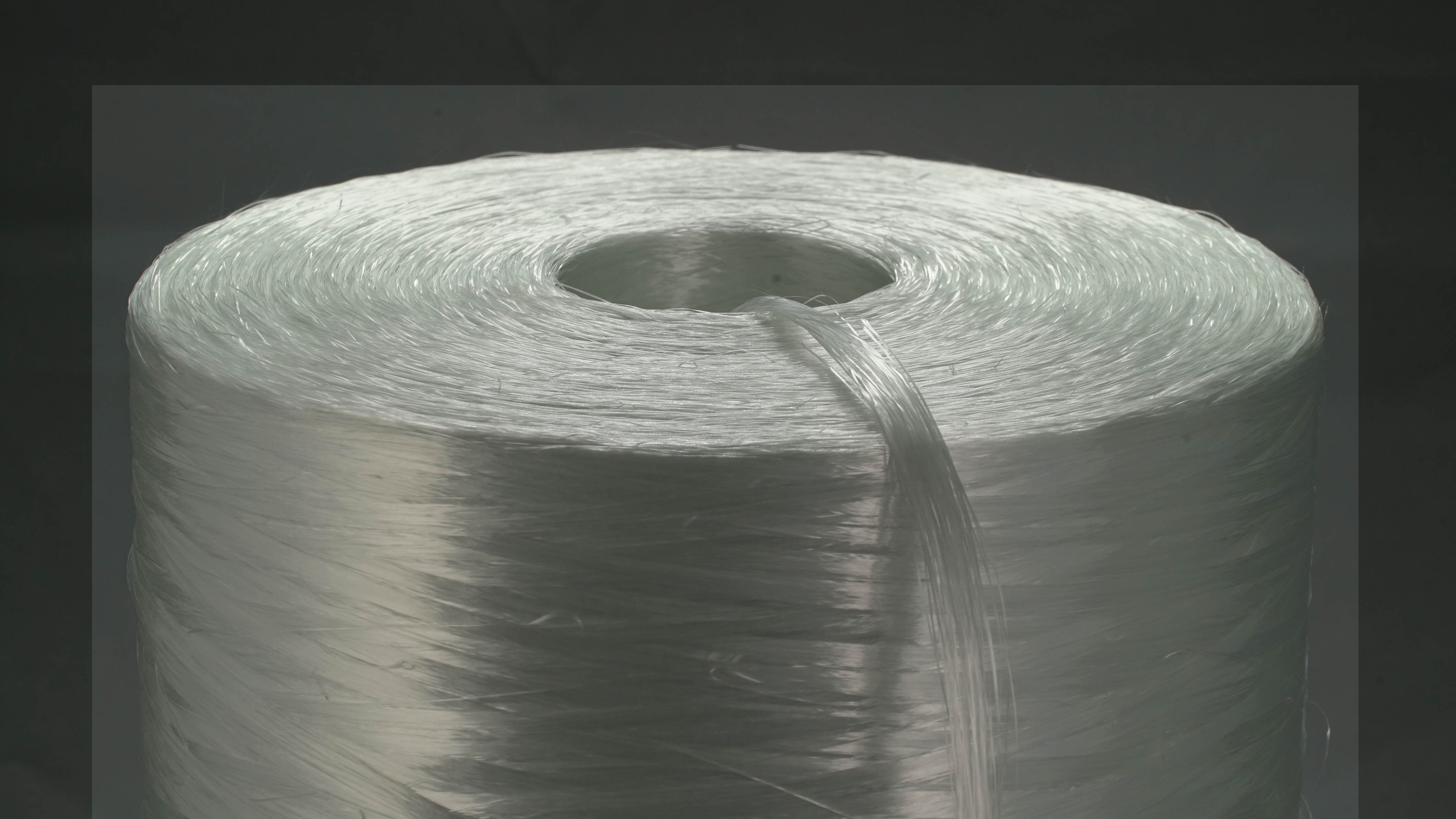

Johns Manville (JM), a manufacturer of continuous filament glass fiber, has introduced at JEC World MultiStar 266 rovings for sheet molding compounds (SMC) reinforcements where white or light-colored SMC composites are required. MultiStar 266 is reportedly used in low-shrink SMC applications based on polyester resin where a homogeneous outlook is necessary, such as sanitary applications, mass transportation (bus and train), building and electrical applications. JM says that SMC composites are durable, recyclable and can save 30% to 50% of CO2 emissions during the life-cycle compared to steel.

‘The improved performance of MultiStar 266 Roving allows SMC compounders to expand the use of composites in new applications where composites parts do not need to be coated, thus eliminating the energy intensity steps of painting with significant high volatile organic compounds (VOC) emissions,’ said Karin Demez, portfolio leader in JM’s global fibers business. ‘Stationary non-painted SMC applications reduces up to 50% energy use, CO2 emissions, ozone and acid rain water vs. competing materials during its life-cycle.’

This story is adapted from material from Johns Manville, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.