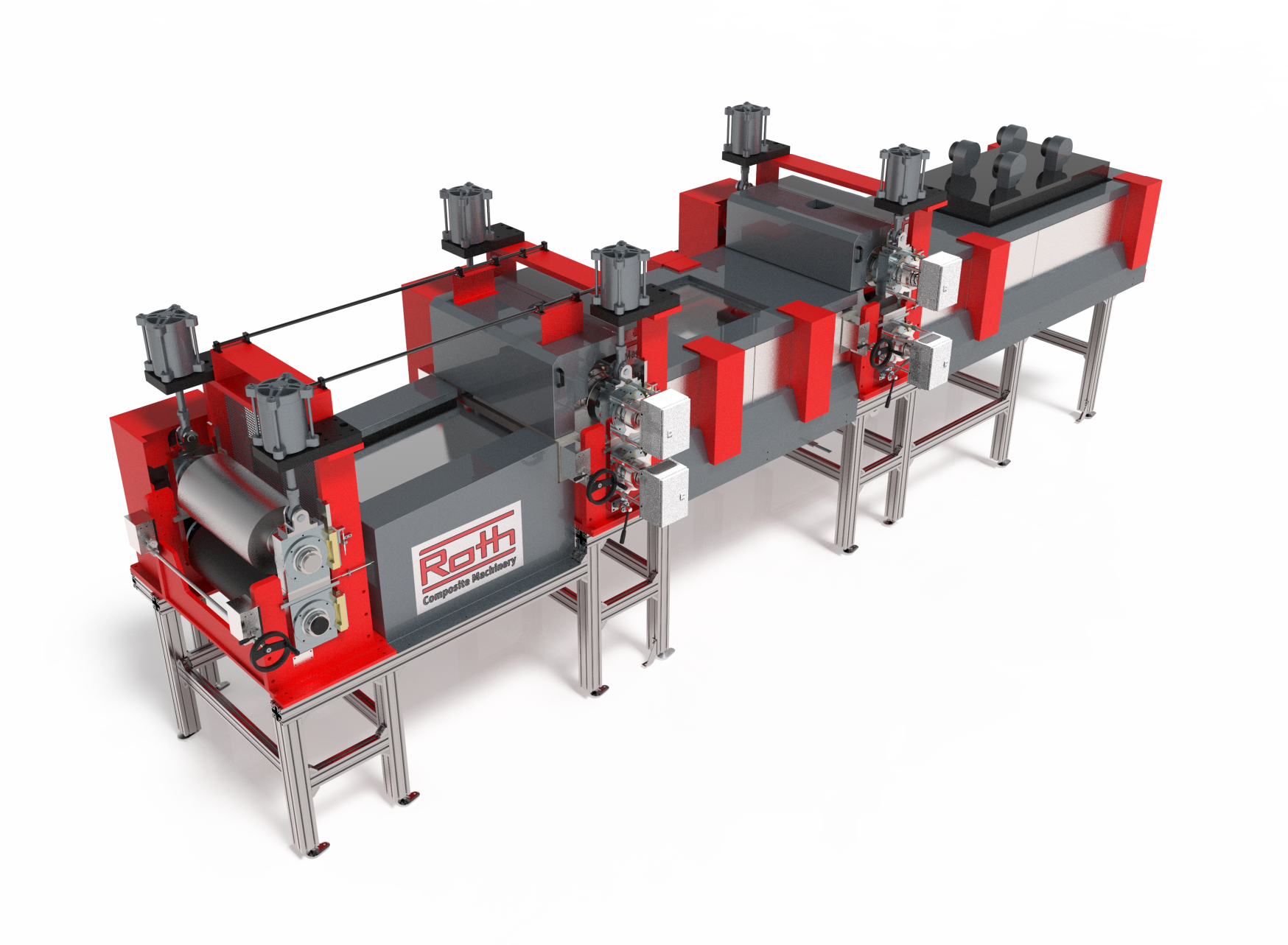

Roth Composite Machinery has introduced a new laboratory line for prepreg as well as organic sheet applications.

The new €1 million plant will also customers and raw material producers to make trials with new matrix systems, fibers and fabrics without having to interrupt their own production processes, the company says. The prepreg laboratory line can process thermoplastic matrix systems up to 400°C to make semi-finished fiber composite materials. These materials can be processed to finished products in later working steps by pre-impregnated, partly cured and thermoplastic matrices. The line is based on calendering technology by using two calenders, a working width of 600 mm and a working speed ranging from one to 40 m per minute. The first calender is installed between the two heating plates and serves for the homogeneity of the prepreg. The second calender can be found at the end of the heating section to help finish of the product.

The machine allows individual research and test runs for all kinds of fibers and resins and a powder dosing unit for the processing of powder or granulate instead of a foil can be integrated. As application systems for the matrix, the comma blade or the Foulard method can be selected. As the application unit is movable, units of customers can be used as an alternative. The plant of Roth offers a spool creel with 80 spool positions, eight unwinders as well as three rewinders and enables a special fiber spreading.

This story is reprinted from material from Roth, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.