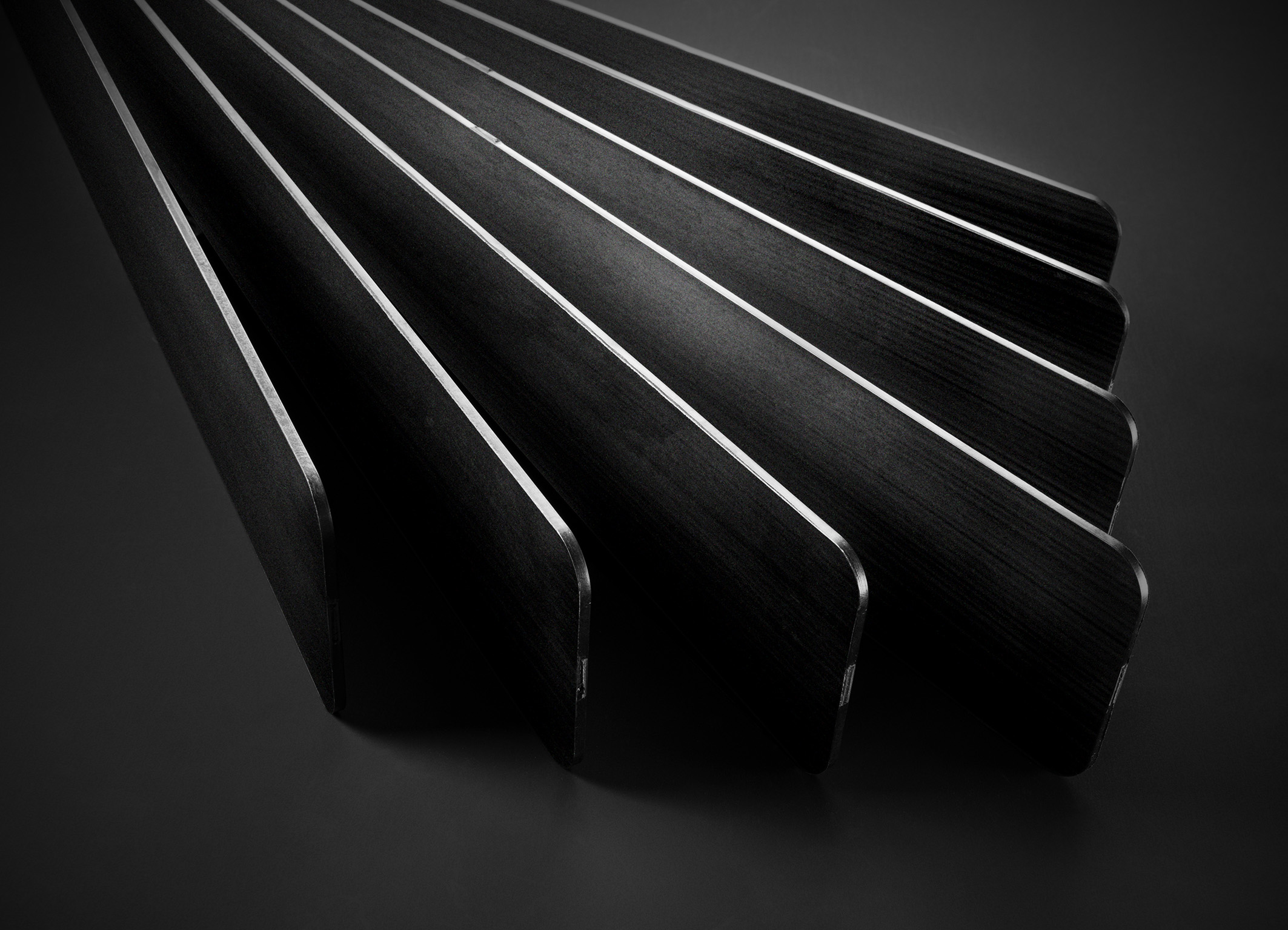

BASF says that its Ultramid Advanced polyphthalamide (PPA) range now includes carbon-fiber reinforced grades with fillings of 20, 30 and 40%.

According to the company, the new materials are suitable for lightweight parts that can safely replace aluminum and magnesium without loss in stiffness and strength and are electrically conductive.

The reinforced materials also have high dimensional stability due to low water uptake, excellent chemical and hydrolysis resistance, high strength and modulus, BASF said.

They can be used to make automotive structural parts for body, chassis and powertrain; pumps, fans, gears and compressors in industrial applications; and components in consumer electronics.

According to BASF Ultramid Advanced N3HC8 with 40% carbon fiber filling shows a better strength and modulus at 80°C (conditioned) than magnesium or aluminum, while carbon-fiber grades reinforced with 20% carbon fibers are about 20% lighter than PA6 or PA66 filled with 50% glass fibers.

‘Our new PPA compounds with carbon fibers are the ideal metal replacement,’ said Michael Pilarski, PPA business management at BASF. ‘Lately, we have seen safety issues at magnesium producers in different countries, which makes the supply rather unpredictable. Producing parts out of magnesium or aluminum also requires additional post-processing and tooling which increases system costs. Given the opportunities for 25 to 30% weight reduction with our new PPA grades, we can offer a safe, cost-efficient and high-performance alternative for parts traditionally manufactured from metal.’

This story uses material from BASF, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.