CompoTech has launched a new standard range of lightweight carbon fiber (CF) epoxy composite beams in round tubes and square shaped options and sizes.

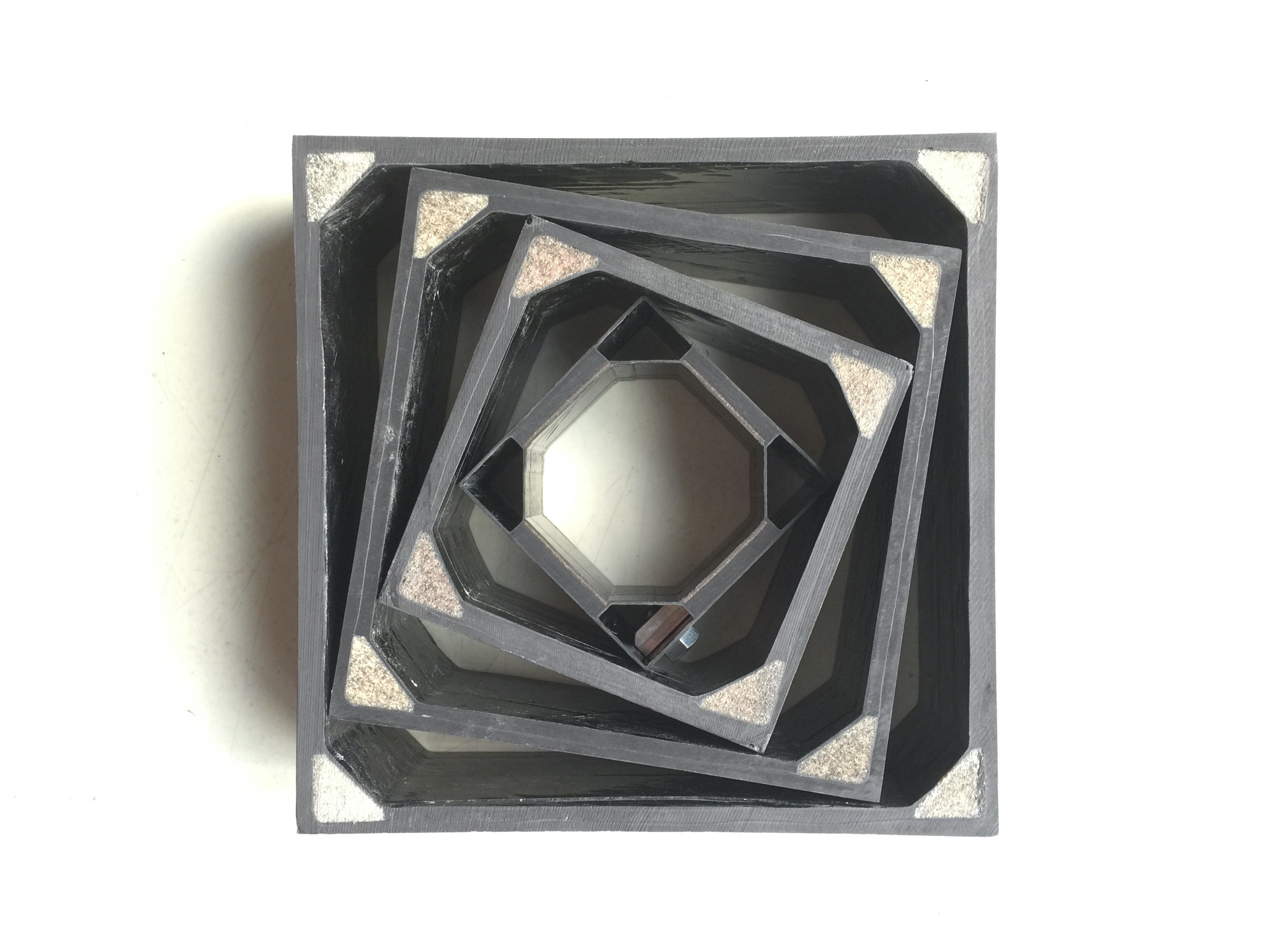

The standard square beams, which can replace steel, are produced from graphite and PAN carbon fibers using the company’s automated, robot assisted filament placement technique, which places continuous fibers axially along the beam length. According to CompoTech, this can make a high strength carbon epoxy composite beam with 10-15% higher stiffness in the axial direction and up to 50% greater bending strength when compared to a conventional filament wound beam with the same dimensions.

The beams are suitable to make industrial machine tool beams, drive shafts, automated automotive press line T-booms, structural frames and crossbars, crop sprayer booms, aerospace structures, yacht masts and spars and composite bike frames. CompoTech’s standard square beam options include hollow cornered ‘bolt together’ connector beams to extend length, and beams designed with reinforced corners for added stiffness, damping and load bearing performance.

This story uses material from CompoTech, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.