Non-contact precision measurement specialists Imetrum will be promoting its new integrated material testing system, UVX, at CAMX Composites and Advanced Materials Expo, which takes place from 16 –19 September 2016 in Anaheim, USA.

Imetrum's UVX system is designed to integrate with the majority of manufacturers' test machines. The system is also designed to handle a large percentage of the ASTM tests methods and uses standard material testing language and terminology.

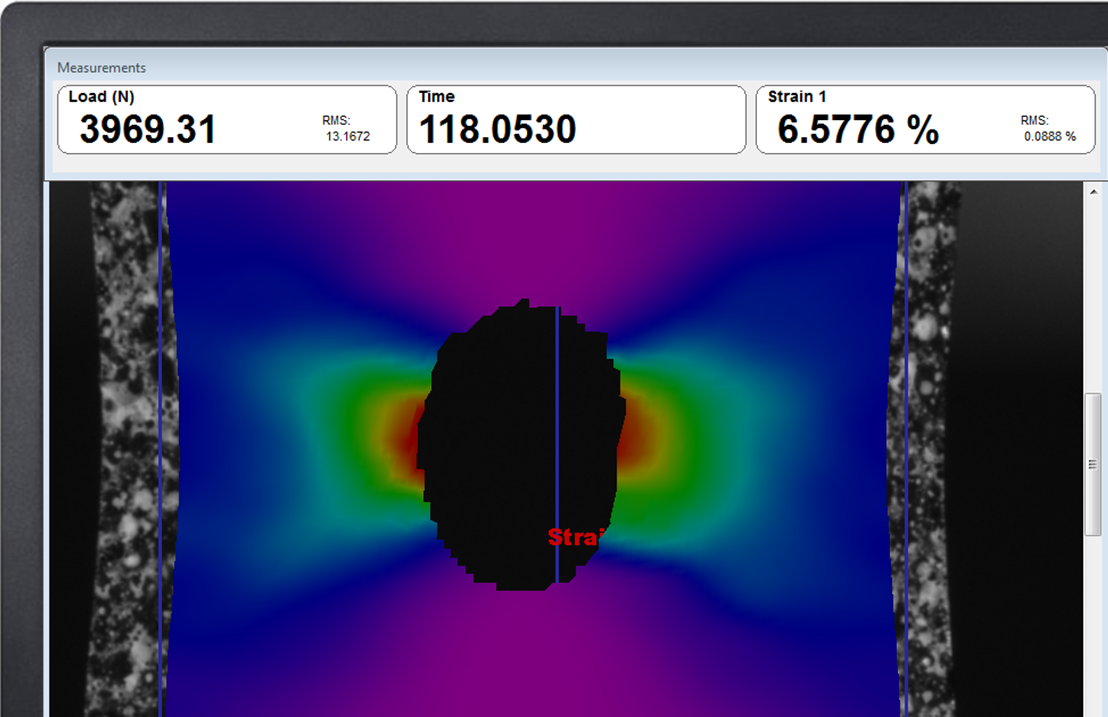

Both the Universal Extensometer (UVX) Flexi and 3D Precision Displacement Tracker (PDT) systems, for material testing and component and assembly testing, are based on Imetrum's Video Gauge software. Each system offers measurement tools such as two and three dimensional optical LVDTs and measurement of true shear strain. Imetrum will also be demonstrating one of its software tools at the show. The Strain Map tool is application specific and measures and displays strain and displacement gradients.

‘Video Gauge software can be used to extract deformation and strain data from any test, irrespective of scale, so long as a stream of images can be obtained,’ said Ian Bond, head of department of aerospace engineering, Advanced Composites Centre for Innovation and Science, University of Bristol. ‘For low speed testing on conventional test machines this data can be extracted in real time up to at least 300Hz. It can also be used in conjunction with the high speed camera post-test. When coupled with a miniaturised test machine and a metallurgical microscope this gives us the capacity to carry out very fine scale studies of the strains within loaded composites at the meso and micro scales.’

This story is reprinted from material from Imetrum, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.