Lanxess says that it has carried out a range of tests to investigate the fire behavior of its overmolded polyamide-6-based Tepex.

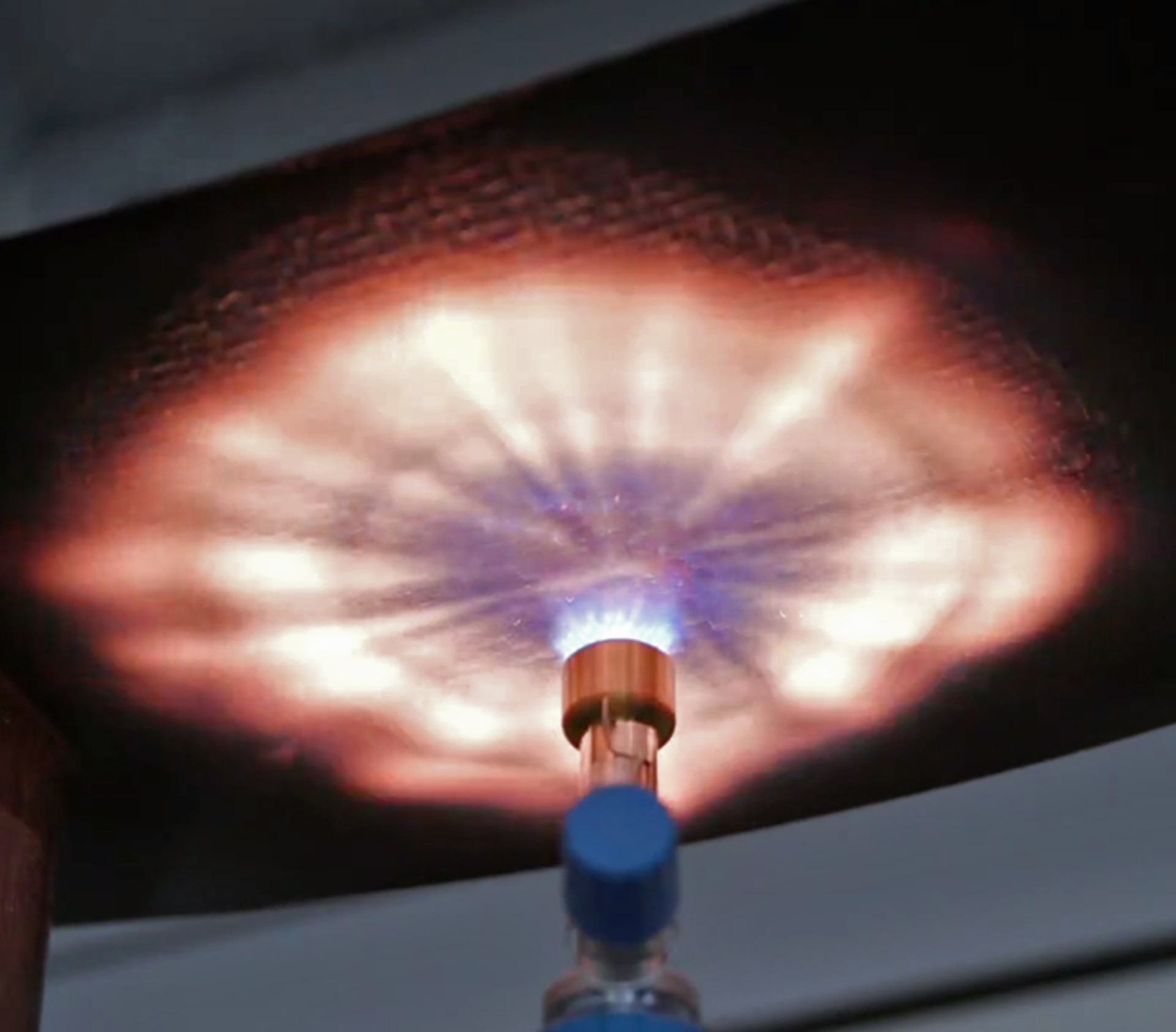

The company tested a U-shaped profile made of Tepex, which the inside reinforced with crosswise ribs made of various polyamide 6 types such as Durethan, with or without a flame-retardant package. The practical test specimen was exposed to a 900°C flame in six positions for between 30 seconds and five minutes.

According to the company, the Tepex confirmed its fire resistance because only the molded rib material was burning after five minutes of flame treatment, and only when it was not equipped with special flame retardants. Where the ribs and overmolded areas were from a flame-retardant polyamide, the flames did not spread from the site of the fire treatment, but rather died when the burner is removed.

‘So, using non-flame-retardant Tepex with a flame-retardant injection molding material offers a very substantial safety margin for the design of flame-retardant components.

We see enormous potential for this material combination to be applied in high-voltage battery components such as housings and partitions, but also in floor plates for inductive battery charging systems,’ said Dr Stefan Seidel, head of research and development at Bond-Laminates, a Tepex company.

This story uses material from Lanxess, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.