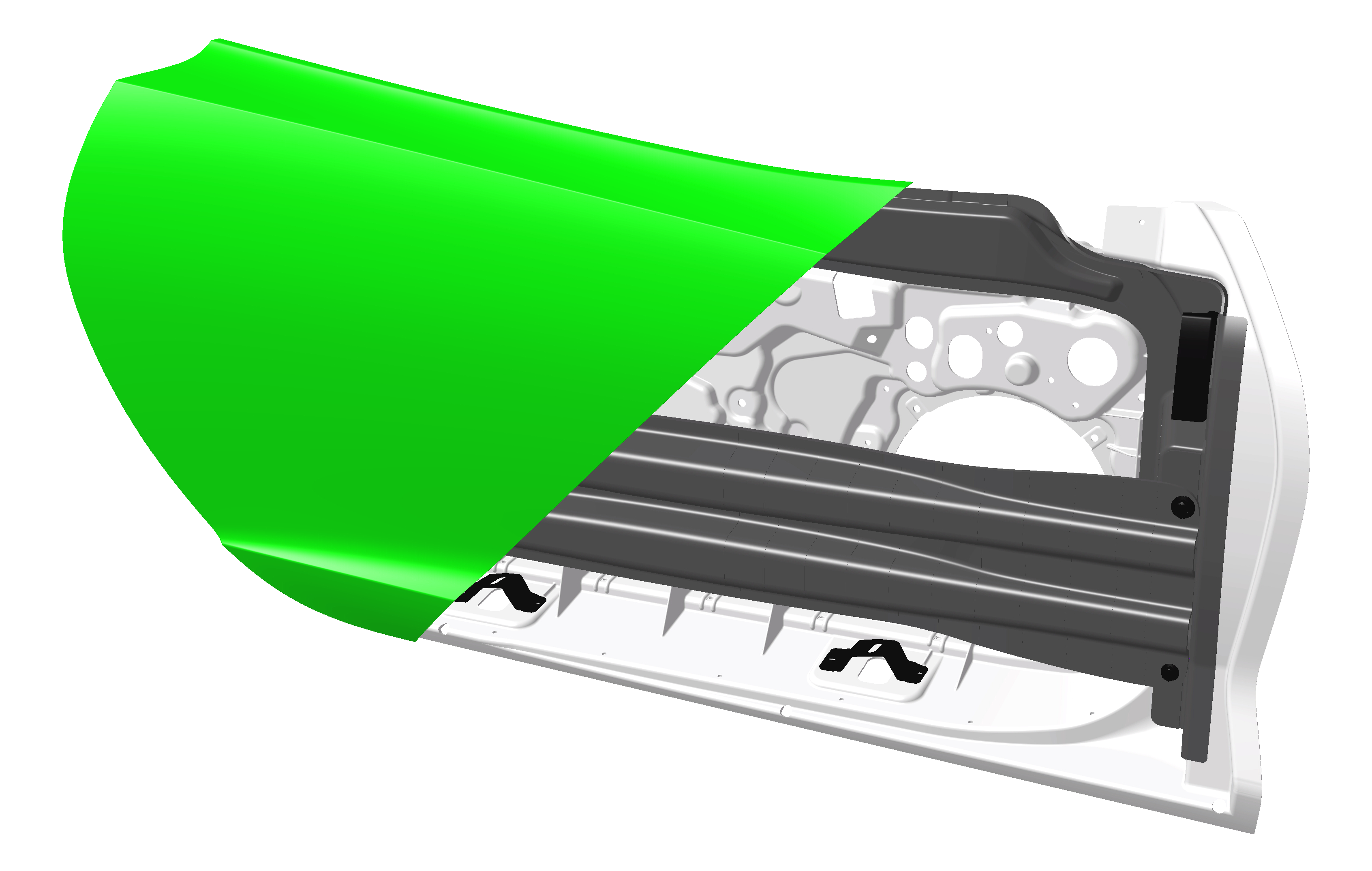

Teijin Limited has reportedly developed a multi-material composite automotive door prototype that maintains required crash specifications while reducing overall weight by 35% when compared to a conventional steel door. The module is made from carbon fiber sheet molded compound (SMC), glass fiber SMC and unidirectional glass fiber reinforced plastics (GFRP). The company says that it is also equal in cost to that of an aluminum door module. The door can also withstand the heat level of the E-coat automotive painting process. According to the company, door components must meet especially demanding requirements for shock absorption to protect passengers in crashes, fatigue resistance to withstand the stresses of repeated opening and closing and accommodate interior harnesses for electrical wiring and signal components. Teijin says that it plans to launch a commercial door module by 2025.

This story uses material from Teijin Limited, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.