Arevo, which makes composite manufacturing software, has formed a partnership with bike manufacturer Franco Bicycles to make a 3D printed, continuous carbon fiber single-piece unibody frame.

The frame will form part of a new line of eBikes Franco will sell under its Emery brand.

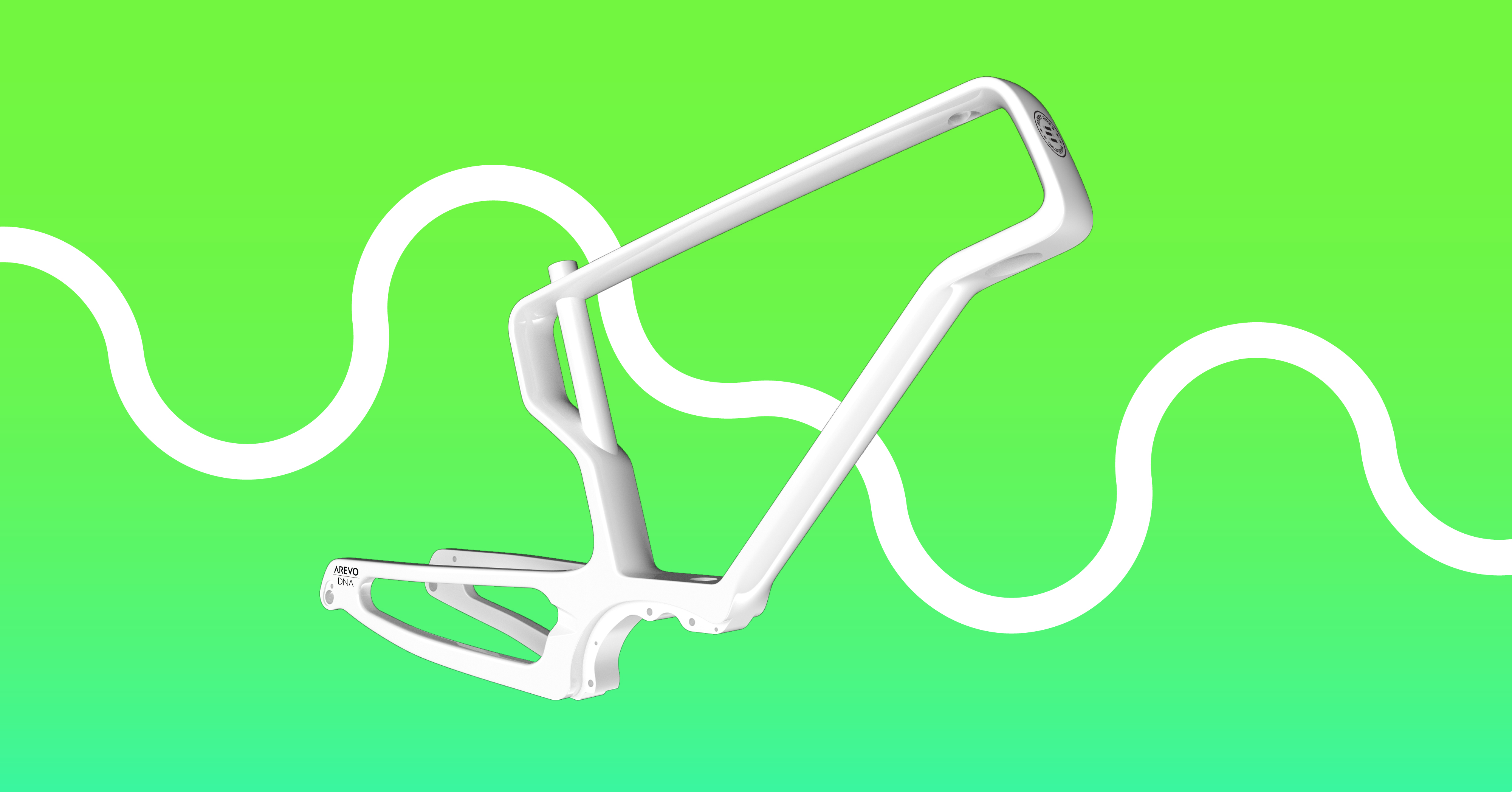

The Arevo frame is made as a single part, in contrast to current composite frames, which are made of many parts glued together, the company says. It features continuous carbon fiber placement and improved structural integrity and stability.

Arevo adds that this technology could lead to volume production of AM-made composite parts made with thermoplastic materials, which are tougher, durable and recyclable, as compared to brittle and non-recyclable thermoset materials, a replacement of a laborious manual process with a fully-automated, production model, and much greater freedom of design.

‘This is the first composite additive-manufactured bike frame and it represents an important milestone for the AM industry as Arevo is delivering on the promise of on-demand manufacturing of composite parts in volume now,’ said Hemant Bheda, Arevo co-founder and chairman. ‘With the introduction of the Emery One, the transformation of the global composite bike industry has begun.’

This story uses material from Arevo, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.