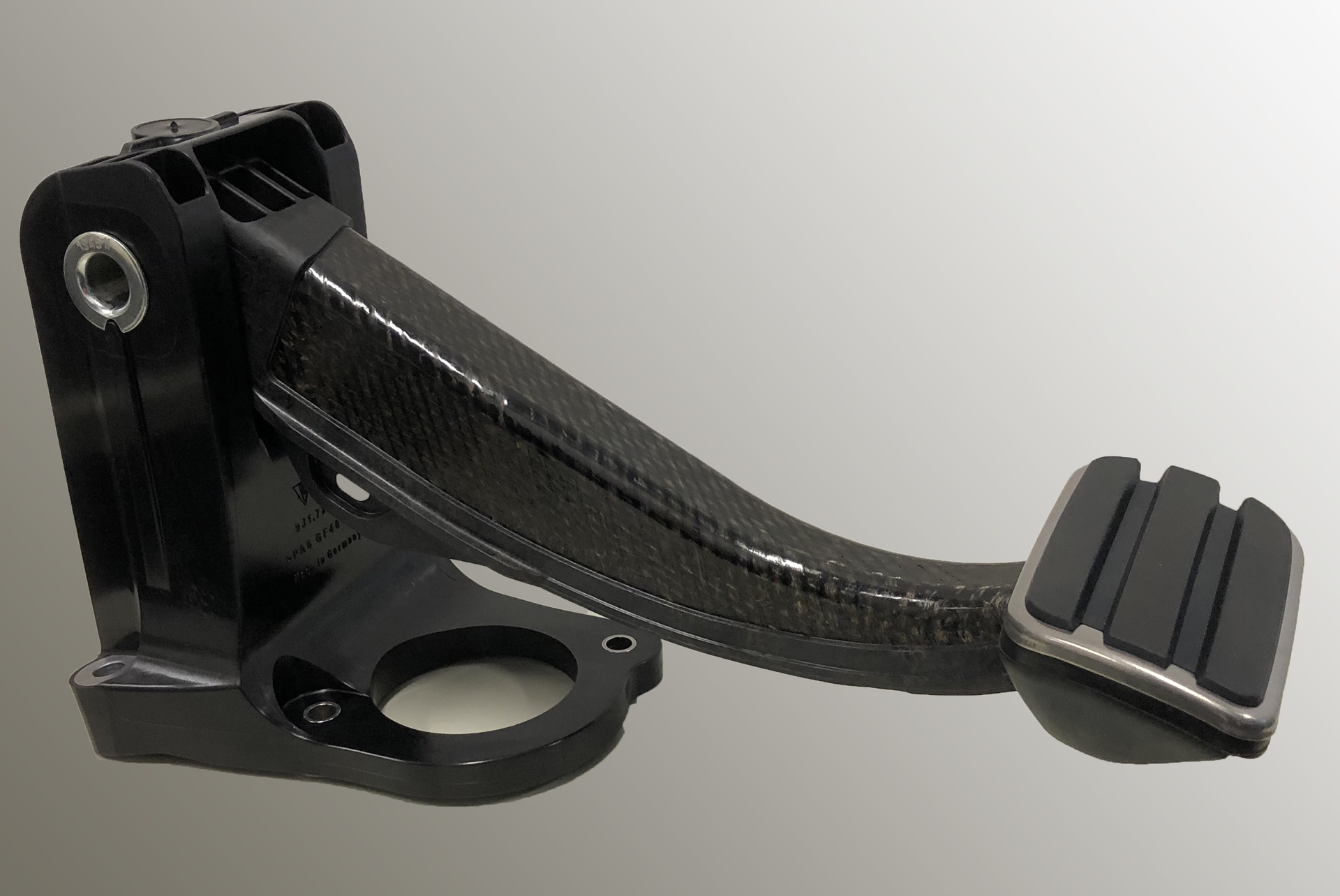

Lanxess has supplied a composite insert for what it says is the world’s first all-plastic brake pedal in electric sports car.

The insert made from Tepex dynalite continuous-fiber-reinforced thermoplastic composite and several tapes, gives the brake high mechanical strength and very low weight, the company said.

According to the company, Tepex dynalite has a thermoplastic matrix that is typically reinforced with layers of continuous glass-fiber fabric. The brake pedal for the battery-electric sports car uses a composite structure with a polyamide 6 matrix, which contains unidirectional fiber layers inside and fabric layers with fibers arranged at 45° angles on the two covering layers, and features multiple tapes with glass-fiber rovings to reinforce the bottom of the component.

Since the tapes and the Tepex insert consist of mutually compatible plastic matrices, the tapes can be welded onto the Tepex insert using a laser, Lanxess says. This results in laminates with fiber layers that follow the load paths more precisely and are adapted to the exact load-specific component requirements. The covering layers of the insert with their 45° fiber layers, combined with the tapes on top, help ensure the high torsional strength of the pedal, according to the company.

Lanxess says that there are currently four different brake pedal designs in mass production based on an all-plastic version, while for all component versions, the load paths are also improved to suit the various torsion directions. The brake pedals are made in an automated process using hybrid molding in short cycle times, making them suitable for large-scale production. The method integrates draping of the Tepex insert and the tapes in the subsequent injection molding process.

‘The composite structure makes the brake pedal 50% lighter than a comparable steel design,’ said Dr Klaus Vonberg, who specializes in lightweight design Lanxess. ‘The structural component meets the demanding load requirements thanks to the tailor-made fiber-layer construction of the Tepex insert and additional local tape reinforcement. Extensive automation allows the geometrically complex safety-critical component to be manufactured efficiently and in a way that is suitable for large-scale production.’

‘This tailor-made fiber-layer structure and the combination of organic sheets and tapes have made it possible to reduce brake pedal weight even further while simultaneously achieving the exceptionally high level of mechanical characteristics that such a safety-critical component needs to provide,’ added Dr Daniel Häffelin from at BOGE Elastmetall, the company that designed the brake pedal.

This story uses material from Lanxess, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.