The 8 inch (203 mm) diameter clay pipe had been in service for more than 50 years.

When the pre-installation video showed active leaks in the pipe, engineers were concerned how the deterioration might affect a traditional CIPP liner. With traditional CIPP, the pipe is fitted with a new liner impregnated with resin that cures when exposed to heat. Active leaks creates cool spots which can result in incomplete and lower mechanical properties.

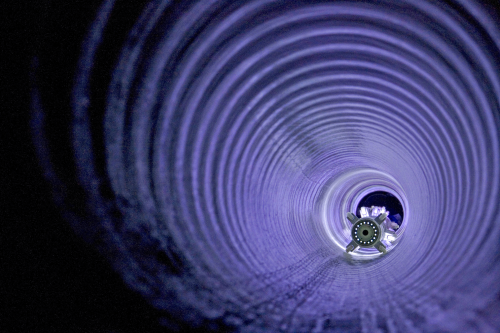

To avoid this situation, engineers decided to have the pipe repaired with BLUE-TEK® ultraviolet (UV) cure technology from Reline America Inc, Saltville, Virginia, USA.

Reline America is the exclusive North American partner for BLUE-TEK CIPP liner and UV curing equipment technology established by Brandenburger GmbH, of Landau, Pfatz, Germany. This combines a fiberglass fabric impregnated with UV cure unsaturated polyester resin to produce a high quality, high strength liner inside the host pipe.

UV cure resin

The fibreglass fabric liners for the job were impregnated with Vipel® unsaturated polyester resin from AOC Resins, which is formulated for UV cure. Because the resin hardens when exposed to UV light instead of heat, BLUE-TEK impregnated liners are not affected by cool spots. These liners can also be shipped without refrigeration, unlike liners which cure when exposed to heat.

“When Knoxville Utilities Board engineers heard that our liner was not affected by active leaks, they decided to use our technology for a pilot project,” says Danielle Verderame, Marketing Coordinator for Reline America.

“The project site was located in a combination residential and industrial area that has very limited access, lots of trees, and is close to buildings. Open cutting and pipe bursting would have been expensive and disruptive options.”

The pilot project for 2991 ft (912 m) was awarded to trenchless pipe replacement specialist Portland Utilities Construction Co LCC (PUCC), headquartered in Portland, Tennessee, USA.

PUCC has years of experience in pipe bursting methods but had yet to perform a CIPP repair. Mike Woodcock of PUCC explained how Reline America technical support and AOC resin helped turn the pilot project into a new capability for PUCC.

| The liners were impregnated with the AOC resin under controlled conditions in Reline’s ISO-certified facility. The AOC resin did everything that was expected – reacting smoothly during installation and performing very well in the finished liner. |

| Mike Woodcock, PUCC |

“Reline America did an outstanding job in training our crew,” says Woodcock. “Their team helped us thoroughly learn the technique and become knowledgeable about the equipment and technology."

The first installation was so successful that right after the pilot phase was finished, the Knoxville Utilities Board added 6533 ft (1991 m) to the project for a total of 9524 feet (2903 m).

PUCC continues to get more UV-cure CIPP projects, including work under Phillip Fulmer Way, a busy street near the University of Tennessee football stadium and basketball arena where any excavation can cause major disruption.