The installation for the city’s Water Utilities Department involved 1433 m of 122 cm underground pipe. The project was designed by Denton’s Utility and CIP Engineering Department, whilst the pipe’s performance is derived from Flowtite design and process technology from US Composite Pipe South LLC (USCPS). USCPS manufactured the pipe with Vipel® resin from AOC.

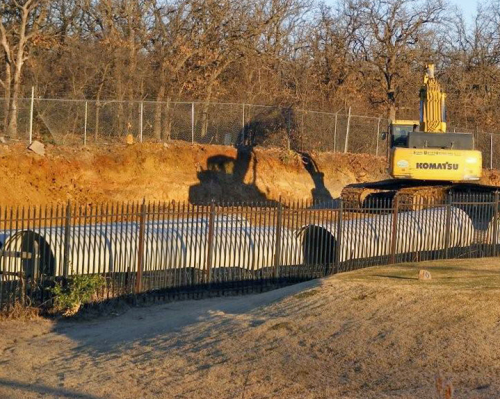

The pipe was installed by Texas United Excavators under the direction of Project Manager Rocky Hill.

“This was first time we used composite pipe,” says Hill, “and my foremen really like it. Compared to the alternative, which was polyvinyl chloride (PVC), the composite showed no deflection and was installed in less time.”

As a comparison to the alternative 6.4 m PVC pipe, the composite pipe lengths were longer at 8.5 m resulting in 25% less joints.

As required by the state’s Public Works Standards the pipes were joint tested. The protocol calls for holding at a steady internal pressure 0.24 bar for 2 minutes. Then the compressor is detached, and the pressure is observed for a period of 10 seconds. A drop of greater than 1 psi during the final 10 seconds results in a failed test. On this project, every fibre reinforced plastic (FRP) to FRP joint passed on the first attempt.

The Flowtite process manufactures pipe on a continuous advancing mandrel that provides a high production efficiency rate. The composite wall of the pipe is reinforced with a combination of continuous and chopped glass fibre to achieve the optimal balance of cost and performance.

The resin for the Denton pipeline was an AOC Vipel unsaturated polyester resin formulated to Flowtite specifications, ensuring high resistance to the corrosive effects of wastewater and sewer gases.