Teijin Aramid says the prepreg features good anti-ballistic performance and subjected to heat and pressure, it can be shaped into all manner of protective equipment. These include helmets, insert panels for ballistic vests or shaped panels for vehicle protection.

|

In a time where we face potential conflicts in regions around the world, it is important that key protective equipment can be produced where and when it is required. This means the industry needs cost-effective, high performance materials that can be quickly shipped, safely stored and deployed under a range of conditions. |

| Karl Henke, Business Manager of Ballistics, Teijin Aramid |

Longer shelf life

Producers of protective equipment no longer need to install and run expensive refrigerated storage facilities, since the new Twaron PVB prepreg can be stored under normal conditions for an extended period of time.

The company says that systems that are currently used in the industry – based on PVB (polyvinyl butyral)-modified phenolic resins – have a very limited shelf life, since they react to high temperatures and therefore become unusable.

Good ballistic performance

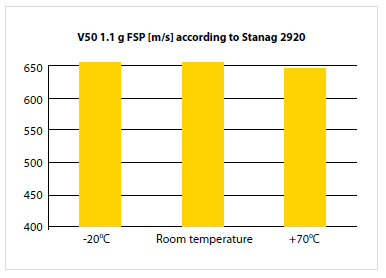

According to Teijin Aramid, performance tests have shown that, both in helmet shells and hard ballistic configurations, the new prepregs ballistic performance against bullets and fragments exceeds that of conventional PVB phenolic systems. In accordance with STANAG 2920, Twaron PVB prepreg has also been tested on temperature tolerance. These tests show very little differences in the ballistic performance between the plates stored at -20°C, +70°C and those stored at room temperature (see chart).

Twaron PVB film has been designed for usage with the same Twaron fabrics that manufacture protective equipment already used today – including Twaron CT736, Twaron T750, Twaron T741, and Twaron T734. During the production process the PVB film is layered and bonded with these Twaron fabrics to form a though, durable material.