Technical Fibre Products (TFP) says this financial investment comes in response to increasing demand for the company’s nonwovens across all markets, including composites.

The new line will be based on the current proprietary wet-laid technology, as used on the existing machines. TFP adds that the new machine will be engineered to extend production capability beyond the current constraints; a key modification will be an increase in production width to over two meters.

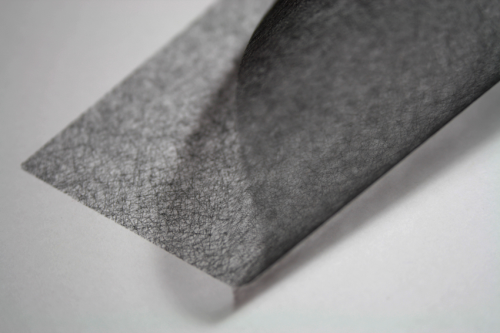

Martin Thompson, managing director of TFP, comments: “The installation of a third production line at TFP is an exciting and necessary step to meet rapidly increasing demand and facilitate the delivery of the company’s successful growth strategy. The installation of the new line is expected to be complete in summer 2015 and represents the latest step in an accelerated programmer of capacity and capability improvements for the company. This includes the installation of a state of the art nan-coating line at TFP’s US manufacturing facility and the commissioning of a high specification flatbed laminator to enable in-house material conversion. The third nonwoven machine will provide a stepwise increase in capacity to support sales growth and provide the opportunity to access new markets for which current production constraints have been a limitation.”TFP says that the design of its process allows it to manufacture nonwovens with a uniformity of fiber dispersion at areal weights from 2 g/m² to in excess of 3500 g/m². A wide diversity of fibre types can also be processed. These include carbon, aramid, glass, polyester, thermoplastic and metal coated carbons, as well as more speciality fibres such as quartz, silicon carbide and pure metals. This fibre range and their associated properties enables TFP’s nonwovens to be used in a variety of applications in industries ranging from aerospace and defence to automotive, energy, industrial, construction and healthcare.