When vacuum bag moulded, SE 84 Nano is reported to exhibit a 20% increase in compressive strength compared with SP-High Modulus’ SE 84LV epoxy prepreg. This is achieved through a combination of proprietary formulation technology from SP-High Modulus, the marine business of Gurit, and 3M Matrix Resin.

SE 84 Nano is said to be ideal for use on components with strength-driven designs such as dagger boards, mast and keel bulkheads, fixing plates, rudders, keel structure and hull inner skin.

For stiffness-driven components, SE 84 Nano provides equivalent stiffness properties with the 20% increase in strength.

SE 84 Nano retains a flexible cure envelope with cure as low as 80°C or for faster moulding of components at 120°C. It is compatible with vacuum bag, press moulding, autoclave and other pressure moulding processes. It can be used in sandwich structures with honeycomb and foam.

“With the launch of SE 84 Nano SP-High Modulus is able to offer customers a high-performance prepreg that can offer a significant increase in compressive strength over our comparable prepregs," reports Graham Harvey, General Manager Marine at Gurit. "We expect that this product will benefit designers, engineers and builders of sailing boats at the cutting edge of performance, who could seek to use SE 84 Nano to achieve lighter parts for the same strength or a strength bonus for stiffness-dominated applications.”

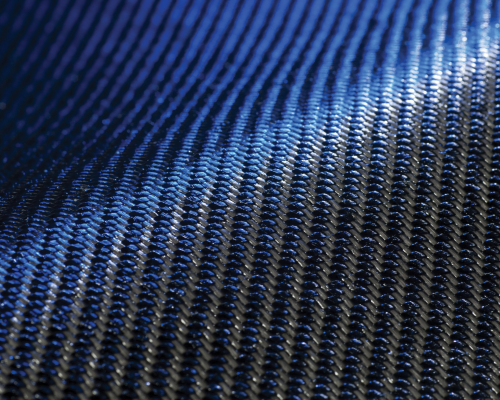

SE 84 Nano prepregs are available in a variety of fabric forms and unidirectional tapes.