These systems can reach Tg values of over 130°C when properly post-cured. They are suitable, for example, for the production of dark painted aircraft, so that despite the higher aircraft skin temperatures that can be caused by the effects of solar heating on the darker paint, the necessary thermal stability is guaranteed.

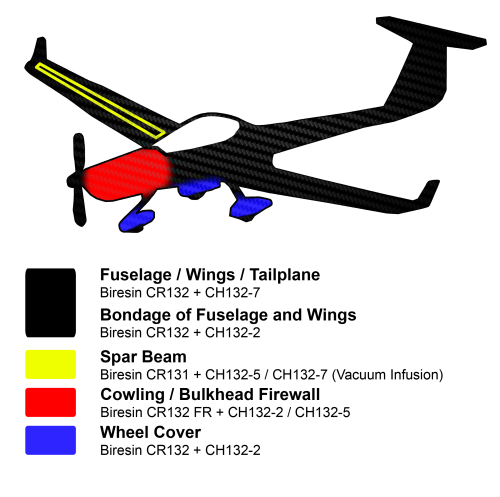

Biresin CR132 resin is a hand laminating base system with three hardeners (Biresin CH132-2, -5, -7), which all offer similar properties but have different pot lives, from 60 to 210 minutes, allowing for efficient production of different size parts.

Based on the properties of the base CR132 epoxy resin and using the building block principle, two further resins have been developed. Biresin CR132 FR which, with the existing hardener Biresin CH132-2, is a special flame retardant (FR) matrix. This can be used, for example, in the production of cowlings and fireproof bulkheads produced by hand lamination. This system, CR132FR/CH132-2, achieved a V-0 rating when tested according to the UL94 vertical flammability test.

The final resin system uses a different resin, Biresin CR131, to allow for processing by vacuum infusion. This resin, with the hardeners CH132-5 and -7 plus another hardener CH135-4, can then be used to produce composites by the infusion process to achieve even higher material performance than those made by hand laminating.

With a total of three resins and just four hardeners Sika offers a complete product family in the form of a modular system, which can give high performance results in a wide variety of applications. These resin systems can also be used wherever these properties are required, not only in light aviation.