EconCore says that its new range of recycled polyethylene terephthalate (rPET) honeycomb is now commercially available and available to licence.

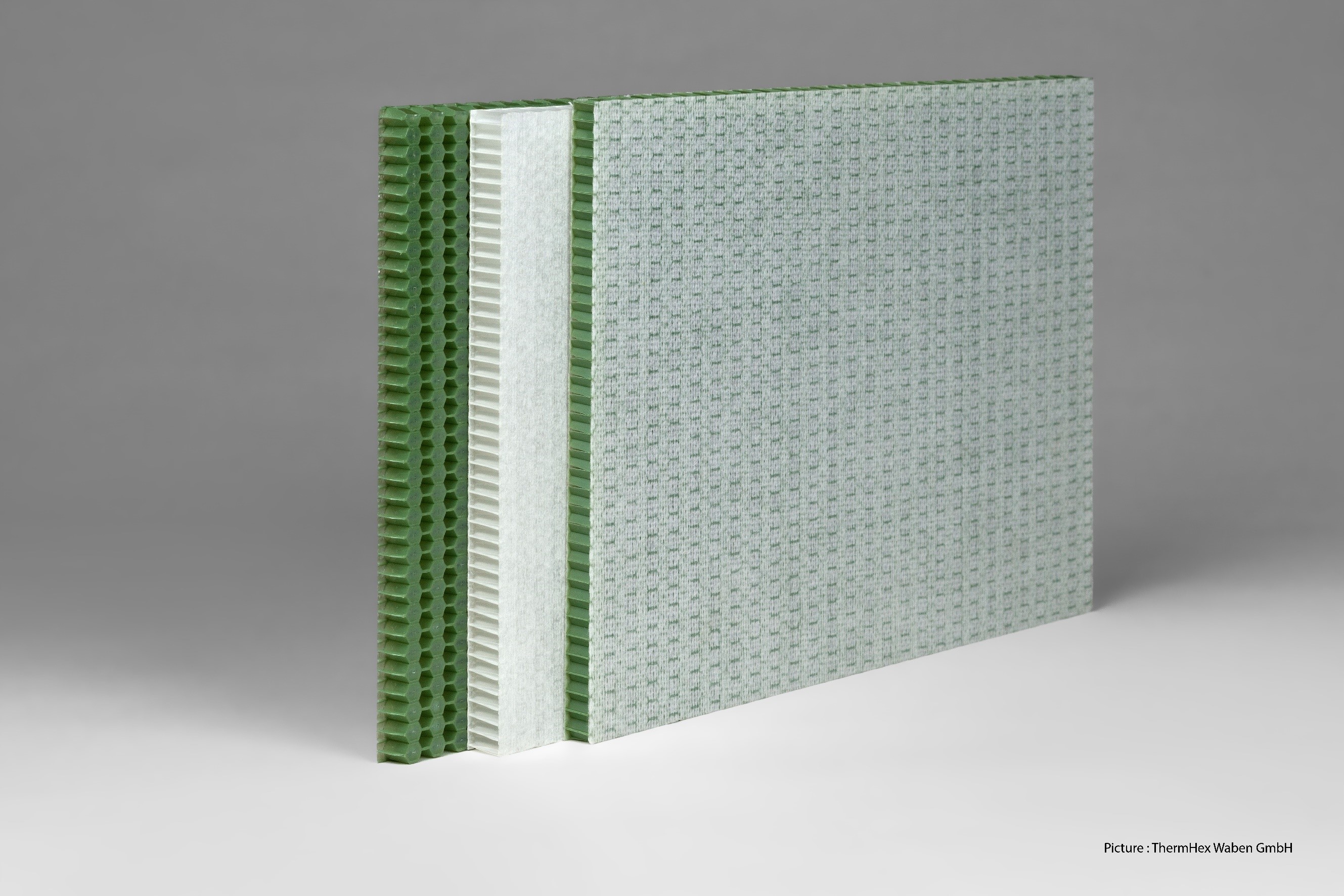

According to the company, the rPET honeycomb core is generally made from more than 95% recycled PET from a variety of sources such as bottles and food packaging. Using the material can reduce CO2, along with already established reductions due to the fuel and energy savings of lower weight products.

Recycled PET honeycomb cores also have improved temperature resistance and mechanical properties when compared to conventional thermoplastic core materials, EconCore says.

‘Adapting [our] technology to successfully use PET and rPET honeycomb is another great step forward,’ said Wouter Winant, technical manager at EconCore. ‘By adjusting the content of additives or fillers, we can optimise the performance characteristics. One key aspect of the development journey was the optimisation of the processing methodology and adapting the equipment in order to increase the efficiency of the continuous honeycomb production process.’

This story uses material from EconCore, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.