Researchers from NYU Tandon School of Engineering have demonstrated that toolpaths used in the 3D printing of composites can also be reproduced with machine learning (ML) tools applied to the microstructures of the part obtained by a CT scan.

According to Nikhil Gupta, a professor of mechanical and aerospace engineering, the additive manufacturing (AM) of carbon and glass fiber composites allows fiber orientation to be improved. This is due to the toolpaths, printer-head orientation instructions for each layer of the component being printed, found within the CAD file.

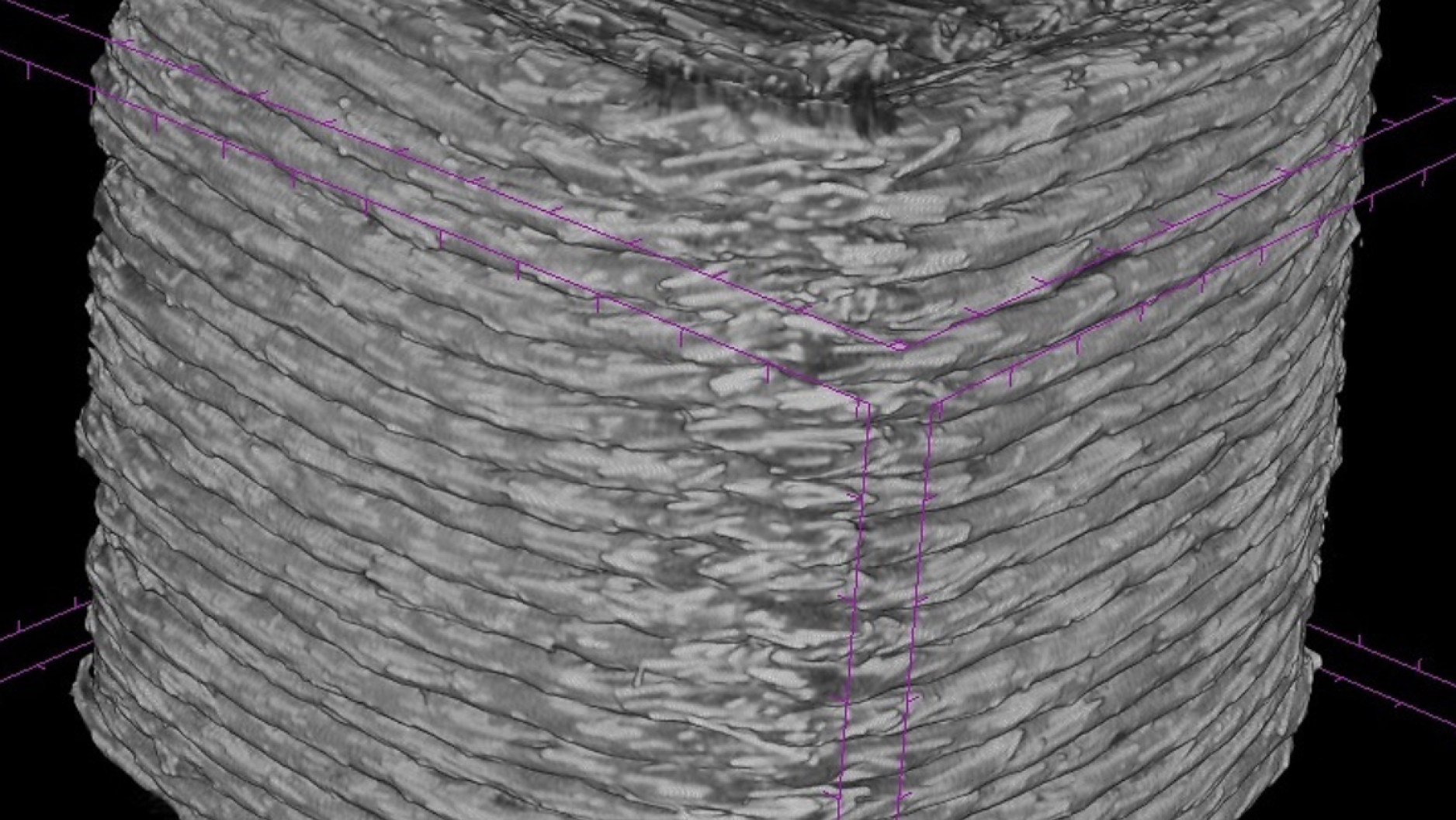

According to the university, its recent research demonstrates a method of reverse engineering this toolpath in the production of a 3D printed glass fiber reinforced polymer filament that, when 3D printed, has a dimensional accuracy within one-third of 1% of the original part.

While the printing direction used during the 3D printing process can be captured from the part’s fiber orientation via micro-CT scan image, the fiber direction is difficult to discern with the naked eye. As a result, the team reportedly used ML algorithms trained over thousands of micro CT scan images to predict the fiber orientation on any fiber-reinforced 3D printed model. According to the researchers, the ML algorithm results were validated on cylinder and square-shaped models, finding less than 0.5° error.

According to professor Gupta, the study raises concerns for the security of intellectual property in 3D printed composite parts, where significant effort is invested in development, since modern ML methods can make it easier to replicate them at lower cost and in a shorter time.

‘Machine learning methods are being used in the design of complex parts but, as the study shows, they can be a double-edged sword, making reverse engineering also easier,’ said Gupta. ‘The security concerns should also be a consideration during the design process and unclonable toolpaths should be developed in future research.’

The research paper, Reverse engineering of additive manufactured composite part by toolpath reconstruction using imaging and machine learning, was published in Composites Science and Technology.

This story uses material from NYU, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.