Engineers from the University of Delaware have reportedly a 3D printing technology that can make fiber-reinforced polymer composites using continuous carbon fibers and thermosetting polymers.

According to the engineers, while 3D printing of composites has been successfully demonstrated using thermoplastic polymers and discontinuous fillers, the resulting composites can have poor mechanical properties and low service temperature.

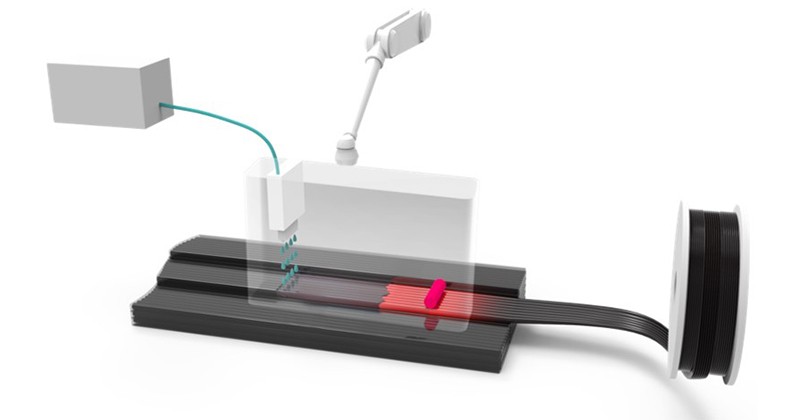

The team developed an approach called localized in-plane thermal assisted (LITA) 3D printing, which allows the user to control the thickness and degree of curing of liquid polymer that solidifies into the desired shape. In LITA 3D printing, the researchers can manipulate the temperature of the carbon fibers, aiding the flow of liquid polymers into channels between the carbon fibers. Then, the polymers are cured, solidifying into a three-dimensional structure. No post-curing is required, according to Kun (Kelvin) Fu, an assistant professor of mechanical engineering at the University of Delaware and the corresponding author of this work.

The team also developed a robotic system that includes a printing head and automated robot arm. This customized 3D printer reportedly allows the group to print a variety of shapes and structures.

‘This is believed to be the first time anyone has achieved such 3D printing of continuous carbon fiber and thermosetting composite,’ said Fu. ‘Continuous carbon fibers and thermosetting resins are very important to make strong and light-weight composites, and they are widely used in many applications, such as aerospace, automotive, and sports products. 3D printing could reduce labor and tooling cost, and fabricate composite in a more energy-efficient, rapid, and reliable way with minimum defects.’

The results were recently published in the journal Matter.

This story uses material from the University of Delaware, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.