Solomon Commercials has been carrying out refrigerated truck and trailer conversions for more than 30 years. The company custom builds refrigerated bodies onto truck and lorry chassis to specific customer needs. In response to increased demand, Solomon Commercials looked for cost effective ways to increase output from its existing production lines.

This was achieved by re-engineering a long established assembly process.

The company eliminated the need for riveting bodywork panels together by switching to using Scott Bader’s Crestabond M1-30 primer-less methacrylate (MMA) structural adhesive, increasing productivity by over 50%. Crestabond M1-30 is now used to bond all the aluminium sections to glass reinforced plastic (GRP) panels and the outer aluminium profiles to vehicle boxes.

One adhesive for all applications

Solomon Commercials has two production units in Rossendale, Lancashire, UK. To suit the variety of bonding applications required for the different refrigerated vehicle body designs, its technical and operations project team worked closely with Scott Bader’s technical experts to find the best solution.

Crestabond M1-30 was selected as its working time of 25-35 minutes and fixture time of 60-80 minutes gave optimum flexibility on the shop floor, enabling the use of only one adhesive for all applications.

Since Crestabond adhesives are primer-less, zero or minimal surface cleaning of the substrates to be bonded is needed. This also saves production time and assembly costs.

The bond strength and fatigue resistance of Crestabond M1-30 is suited for body panel assembly applications with GRP and aluminium. Typical mechanical properties for Crestabond M1-30 of 17-20 MPa for tensile strength, a tensile modulus of 750-1000 MPa and an elongation of >100% are quoted by Scott Bader, based on laboratory test results. The adhesive has already been proven in other demanding applications, such as boat hulls.

Reduced assembly time

Solomon Commercials has experienced overall reductions in assembly times of up to 4 hours, depending on the vehicle size and specification.

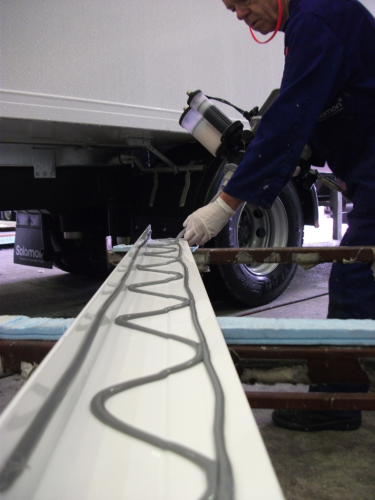

The adhesive was applied using Sulzer Mixpac DXH pneumatic dispensing hand guns used in combination with a Sulzer Mixpac DXR refilling station. These were supplied by MeterMix® Systems Ltd, based in Rushden, Northamptonshire, UK.

The refilling station uses bulk 20 litre pails of Crestabond M1-30 and activator, serving multiple pneumatic hand guns on the shop floor. Sulzer Mixpac DXH pneumatic guns have point of application metering and mixing of the 10:1 ratio MMA adhesive from pressure assisted, refillable adhesive and activator reservoirs located on the gun.

For a limited number of applications, manual hand guns with Crestabond M1-30 400ml co-axial cartridges are also used on the assembly lines.