The pressure indicating film – physically similar to a sheet of paper - is used as a quality control method to correct and prevent defects that result if the preform does not uniformly fill the mould.

Preforms consisting of core materials such as honeycomb, foam and balsa must fill the complex mould consistently. By testing the preform before the resin is injected any modifications required can be made – preventing a bad part from being produced.

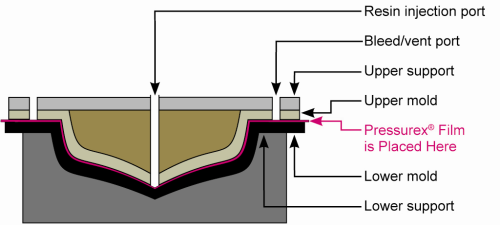

The Pressurex film reveals the distribution of surface contact pressures in cores, composite lay-ups and bonded surfaces. After the fibrous preform is put into the mould, the film is placed on top of the preform and the mould is closed. Without injecting the resin, the mould is then opened and the pressure sensing film is inspected. Areas of high and low pressure are immediately revealed by the film which instantly and permanently changes colour, proportionate to the actual pressure. The precise pressure scale is determined by comparing colour variation results to a colour correlation chart.

Sensor Products says that RTM, vacuum assisted RTM (VARTM) and Light RTM composite parts requiring variable thickness are particularly suited to the sensor film. In areas of low pressure indication, the preform thickness can be enhanced, either with a thicker core material or inclusion of additional fibre. Equally in areas of high pressure indication, the core material can be made thinner, or less fibre can be included.

Pressurex measures pressures of 2-43 500 psi (0.14-300 kg/cm2) and is available in several different pressure ranges. The film is flexible and thin (4-8 mm thick) and can be hand or laser-cut to any size or dimension and conforms to curved surfaces.

Pressurex has a variety of uses in manufacturing process control and machine/component inspection. Snapshot imaging results of the film can be used as a control to compare processes and tools.