British marine glazing manufacturer Trend Marine Products Ltd, Norfolk, UK, has developed the line, opening up a number of new design possibilities for a growing number of production boat builders.

ACG has developed the VTM260 range of low viscosity epoxy prepregs specifically for large component manufacture by vacuum bag oven cure processing. The VTM260 range can be cured between 65°C and 120°C and all share the same basic resin chemistry. Each is formulated to a specific viscosity profile to optimise prepreg manufacture, handling characteristics and reinforcement impregnation. The VTM260 Series can be impregnated into a range of fibres typically carbon, glass and aramid in unidirectional, NCF and woven fabric configurations that are suitable for a variety of marine applications, including hulls, masts, decking, superstructures and bulkheads.

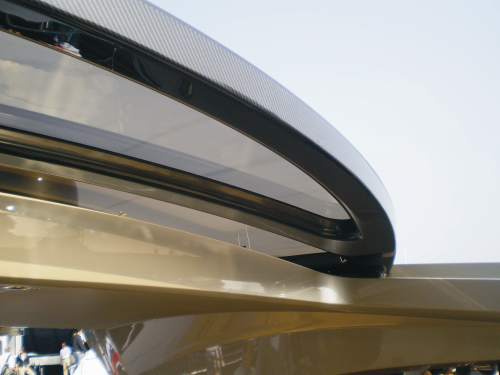

Using ACG’s prepregs and its composites manufacturing expertise, Trend Marine now supplies the largest OEM manufacturer in the world. The recently launched Predator 54 and 60 yachts built by Sunseeker International Ltd, Poole, UK, have benefited from the application of ACG’s advanced prepreg materials. Working to a stringent design specification, Trend Marine built and delivered a composite sliding roof system that was both functional and attractive, meeting every requirement laid down by Sunseeker.

The roof panel, as with any structure positioned high on the boat, is weight critical. The weight has a direct bearing on the stability of the craft and also the mechanisms which operate the roof. Equally, the roof structure must be stiff. Its sleek, slender skeletal frame must span a 3 m aperture while also supporting the plate glass glazing, and prevent flexure, which could jam the mechanism or cause vibration at the near 50 knot speeds that the Sunseeker yachts can achieve.

The vacuum only processing VTM260 prepregs have proved highly effective, combining structural efficiency and low cost processing. ACG’s VTF261 cosmetic surface ply creates the desired aesthetic 'carbon' surface finish, resulting in a solution that is in harmony with the light, airy ambience of the exquisite cockpit. Considering the success of the carbon roof panels in this application, Sunseeker is now looking at using the concept on other models.

ACG will be showcasing its VTM260 prepregs at the METS 2009 marine show, which takes place between the 17th and 19th November in Amsterdam.