The German company has developed integrated inline quality control systems for CFRP production processes. By applying these systems, it can be ensured that all products leaving a factory are 100 percent defect-free, says Pixargus.

With the exception of weight per area, all measurements and inspections are based on optical methods. A key element of the technology is the Pixargus WebControl CarbonFiber system, which inspects the web surface. Along with the framework software architecture, which has been specifically developed for the inspection of these type of surfaces, it is possible to map the complex web structure while detecting defects typical of carbon fibre material.

As a general contractor for total quality control systems, Pixargus supplies several interlinked measuring systems and the data can be combined by the various sensors into a global data map, which allows an overall analysis to be made.

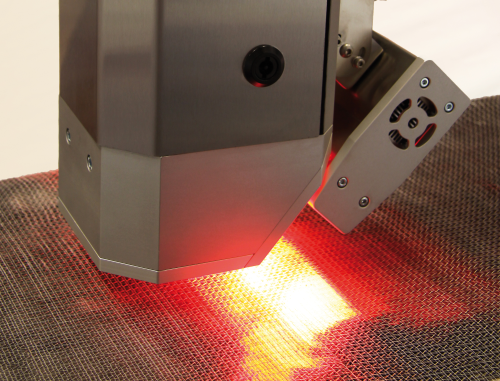

This systems approach is characterised by a wide array of applied technologies, namely surface inspection of the heavily textured fabrics by means of complex image processing and pattern recognition algorithms, optical measurement with an accuracy down to a micrometre, lighting solutions using LED technology and non-contact thickness measurement.

An example of these systems solutions is the inline inspection of the carbon fibre fabrics used to make car body components for a new generation of electric vehicles made by a leading German premium car producer. The system comprises hybrid quality assurance systems for measurements and inspections during processes as diverse as the application of powder, the detection of missing bundles, the analysis of material flaws and sintering.